Introduction

Woodworking enthusiasts and professionals alike understand the importance of having the right tools for their craft. One such essential tool is a wood lathe, a versatile machine used to shape and create intricate designs on wooden objects. In this guide, we will explore the various aspects of using a wood lathe, including its benefits and techniques. Additionally, we will introduce SYIL's CNC wood lathe, a cutting-edge machine that combines precision and safety for optimal woodworking results.

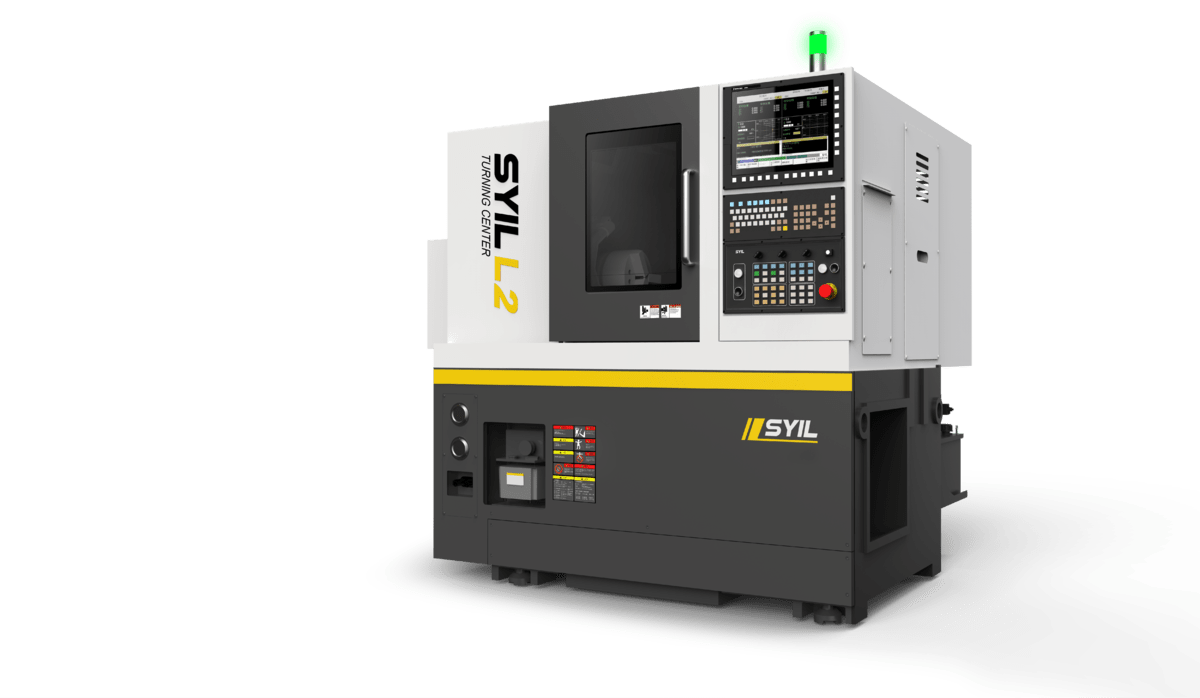

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Among their impressive range is the SYIL CNC wood lathe – an advanced tool designed specifically for woodworking enthusiasts who seek accuracy and reliability in their projects.

Getting Started with a Wood Lathe

Setting up your workspace efficiently is crucial when it comes to using a wood lathe. Before diving into the exciting world of woodturning, make sure you have a dedicated area that provides ample space for maneuvering the lathe and storing your tools.

Setting up your workspace efficiently

Understanding the different parts of a wood lathe

Before you can begin using a wood lathe, it's essential to familiarize yourself with its various components. The main parts of a typical wood lathe include:

1. Bed: This is the horizontal base of the machine where all other components are mounted.

2. Headstock: Located at one end of the bed, this houses the motor and spindle assembly.

3. Tailstock: Positioned at the opposite end of the bed, it provides support for longer workpieces.

4. Tool Rest: A metal bar that supports cutting tools during operation.

5. Banjo: A movable bracket that holds and adjusts the position of the tool rest.

6. Faceplate or Chuck: Used for securing workpieces onto the spindle.

By understanding each part's function, you'll be able to operate your wood lathe more effectively and safely.

Safety precautions when using a wood lathe

Safety should always be a top priority when using any power tool, including a wood lathe. Here are some essential safety precautions to keep in mind:

1. Wear appropriate protective gear, including safety glasses or goggles, ear protection, and a dust mask.

2. Securely fasten workpieces to prevent them from becoming projectiles during operation.

3. Keep loose clothing, jewelry, and long hair secured to avoid entanglement with the rotating components.

4. Always ensure that the lathe is turned off and unplugged before making any adjustments or changing tools.

5. Take breaks when needed and avoid working when you're tired or distracted.

Remember, accidents can happen in an instant, so it's crucial to prioritize your safety at all times.

When it comes to precision and safety in woodturning, SYIL's CNC wood lathe stands out as an excellent choice. With its advanced technology and robust construction, this machine offers unparalleled accuracy and stability during operation.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Whether you're a beginner or an experienced woodturner, SYIL's CNC wood lathe provides the perfect platform for unleashing your creativity while ensuring utmost precision and safety throughout your woodworking journey.

Choosing the Right Wood and Tools

Selecting the Ideal Type of Wood for Your Project

When it comes to selecting the ideal type of wood for your project, there are several factors to consider. First, consider the purpose of your project. Are you creating a decorative item or a functional piece? Different types of woods have different characteristics that make them suitable for specific purposes.

For beginners, it's recommended to start with softer woods such as pine or basswood. These woods are easier to work with and allow for more forgiving mistakes. As you gain experience, you can move on to hardwoods like maple or oak, which offer greater durability and beauty.

Utilizing Appropriate Woodturning Tools and Accessories

Having the right set of tools is crucial in achieving precision and quality in your woodturning projects. The basic tools every woodturner should have include gouges, scrapers, parting tools, and skew chisels.

Gouges are versatile tools used for shaping and cutting various profiles on a lathe. Scrapers are used for refining shapes and smoothing surfaces. Parting tools help create grooves or separate pieces from the main project. Skew chisels are used for creating smooth and clean cuts.

Maximizing Efficiency with SYIL's CNC Wood Lathe

To take your woodturning projects to the next level, consider using SYIL's CNC wood lathe. With its precision engineering and advanced features, this machine offers unmatched efficiency and accuracy.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. The SYIL CNC wood lathe is no exception, offering state-of-the-art technology that allows for precise control over speed, depth of cut, and other parameters.

Basic Woodturning Techniques

Essential Woodturning Cuts and Techniques

When using a wood lathe, understanding the fundamental cuts and techniques is crucial for achieving desired results. One of the most common cuts is the spindle roughing cut, which involves removing excess material to create a cylindrical shape. By using a gouge or skew chisel, you can smoothly shape the wood while maintaining control.

Another essential technique is the spindle gouge cut, which allows you to create coves, beads, and other decorative details on your turned pieces. With proper tool positioning and controlled movements, you can achieve precise shapes effortlessly.

For beginners looking to enhance their skills further, learning how to use a bowl gouge on a wood lathe opens up endless possibilities for creating bowls and hollow forms. This versatile tool enables you to shape both the inside and outside of your projects with ease.

Creating Basic Shapes and Profiles on a Wood Lathe

Once you have mastered the essential cuts and techniques in woodturning, it's time to explore creating basic shapes and profiles on your wood lathe. With careful guidance from experienced turners or instructional videos tailored for beginners, you can learn how to turn spindles into elegant table legs or even craft intricate wooden pens.

By experimenting with different tools such as parting tools or skew chisels, you can create various profiles like beads, coves, and fillets. These profiles add depth and visual interest to your turned pieces, making them stand out.

Advanced Woodturning Techniques

Woodturning is a versatile craft that allows artisans to create intricate designs and patterns on a lathe. With the right techniques and tools, you can take your woodturning skills to the next level and produce stunning pieces of art. In this section, we will explore more complex woodturning designs and patterns, learn how to incorporate embellishments and textures into projects, and showcase the advanced capabilities of SYIL's CNC wood lathe.

Exploring more complex woodturning designs and patterns

When it comes to woodturning, the possibilities are endless. As you gain experience and confidence in using a wood lathe, you can start experimenting with more intricate designs and patterns. From intricate spirals to ornate flutes, there are numerous techniques you can explore to add depth and visual interest to your turned pieces.

One popular technique is called segmented turning, where multiple pieces of different woods are glued together to create unique patterns and shapes. By carefully selecting contrasting woods and arranging them in various configurations, you can achieve stunning effects that will impress any viewer.

Incorporating embellishments and textures into your projects

To take your woodturning projects to the next level, consider incorporating embellishments such as inlays or decorative elements like beads or burnings. Inlays involve embedding materials like metal wire or crushed stone into the surface of the wood for added visual interest.

You can also experiment with adding textures by carving or burning patterns onto the surface of your turned pieces. This creates a unique tactile experience for viewers while showcasing your artistic skills as a woodturner.

The advanced capabilities of SYIL's CNC wood lathe

SYIL's CNC wood lathe is a game-changer when it comes to advanced woodturning techniques. With its precision and automation features, this machine allows you to create intricate designs and patterns with ease. The computer numerical control (CNC) technology ensures accuracy and consistency in every turn, resulting in flawless finished products.

Imagine being able to program complex designs and patterns into the CNC wood lathe and watch as it effortlessly brings your vision to life. Whether you're a seasoned professional or a beginner looking to explore more advanced techniques, SYIL's CNC wood lathe will undoubtedly elevate your woodworking projects to new heights.

Finishing and Sanding

Proper sanding techniques for a smooth finish:

Sanding is a crucial step in achieving a smooth and polished surface on your wood lathe projects. To start, ensure that your wood lathe is turned off and the piece you are working on is securely mounted. Begin by using coarse-grit sandpaper to remove any rough spots or imperfections on the surface of the wood. Move the sandpaper in a circular motion, applying even pressure to achieve an even finish.

Next, switch to finer-grit sandpaper to further refine the surface. Sand in the direction of the wood grain to avoid creating scratches or marks. Gradually work your way up to even finer grits of sandpaper until you achieve the desired smoothness.

Applying finishes and stains to enhance the wood's beauty:

Once you have achieved a smooth finish through sanding, it's time to enhance the natural beauty of the wood by applying finishes and stains. Finishes not only protect the wood but also bring out its color and grain patterns.

Before applying any finishes or stains, make sure to clean off any dust or debris from sanding. Use a tack cloth or a soft brush to remove any loose particles.

When selecting a finish, consider factors such as durability, sheen level, and ease of application. Popular options include varnish, lacquer, shellac, and oil-based finishes like tung oil or Danish oil.

To apply finishes evenly, use a brush or cloth and follow the manufacturer's instructions for drying times between coats. Apply multiple thin coats rather than one thick coat for better results.

SYIL's CNC wood lathe offers precision for flawless finishes:

When it comes to achieving flawless finishes on your wood lathe projects, SYIL's CNC wood lathe stands out as an exceptional choice. With its advanced technology and precision engineering, this machine ensures consistent results every time.

Whether you are a beginner or an experienced woodturner, SYIL's CNC wood lathe simplifies the finishing process by providing consistent speed control and accurate positioning. This level of precision allows you to achieve professional-quality finishes without the need for extensive manual labor.

Maintenance and Care

Proper maintenance and care are essential for ensuring the longevity and optimal performance of your wood lathe. By following these guidelines, you can keep your machine in top shape for years to come.

Cleaning and maintaining your wood lathe for longevity

To maintain the longevity of your wood lathe, regular cleaning is crucial. After each use, make sure to remove any wood chips or debris from the machine's surfaces, including the bed, headstock, tailstock, and tool rest. This can be done using a brush or compressed air to ensure all particles are removed.

Sharpening and caring for woodturning tools

Properly sharpened tools are essential for achieving clean cuts and smooth finishes on your woodworking projects. To sharpen your woodturning tools effectively:

1. Start by securing the tool firmly in a sharpening jig or holder.

2. Use a grinding wheel or sharpening stone to remove any dull edges from the tool.

3. Maintain a consistent angle while sharpening to ensure an even edge.

4. Finish by honing the edge with a fine-grit sharpening stone or strop.

SYIL's CNC wood lathe requires minimal maintenance for optimal performance

SYIL's CNC wood lathe is designed with durability and ease of use in mind. With its precision engineering and high-quality components, this machine requires minimal maintenance to ensure optimal performance.

The machine's enclosed design helps protect it from dust and debris, reducing the need for frequent cleaning. Additionally, SYIL's wood lathe features self-lubricating bearings that eliminate the need for manual lubrication, saving you time and effort.

Conclusion

Woodturning is a fascinating craft that allows you to transform a simple block of wood into beautiful and intricate designs. Throughout this guide, we have covered important aspects of using a wood lathe, from setting up your workspace efficiently to mastering advanced techniques.

To recap, we discussed the significance of selecting a quality wood lathe that offers precision and safety. A reliable wood lathe, such as SYIL's CNC wood lathe, can greatly enhance your woodworking experience. SYIL Machine Tools is renowned for developing and manufacturing precision CNC machines for milling and drilling, with over 12k machines supplied globally. Their commitment to quality and sustainability makes them an ideal choice for woodworking enthusiasts.

It is the foundation upon which your woodworking projects will thrive. With the right tools and equipment, such as SYIL's CNC wood lathe, you can achieve precise cuts and shapes effortlessly.

Whether you are a beginner or an experienced woodturner, this machine offers unparalleled precision and versatility. Its user-friendly interface allows for easy operation, making it suitable for individuals at any skill level.