Introduction

Are you wondering, How much does CNC cutting cost? Understanding the cost of CNC cutting is essential for any business involved in manufacturing or fabrication. Whether you're considering investing in a cnc knife cutting machine, a professional knife sharpener machine, or exploring china knife grinding machine options, knowing the factors influencing CNC cutting costs is crucial. By understanding the importance of knowing CNC cutting expenses, you can make informed decisions to maximize efficiency and cost-effectiveness in your operations.

Understanding the cost of CNC cutting

When it comes to CNC cutting, the cost involves more than just the initial purchase of a machine. It includes factors such as material costs, labor costs, maintenance costs, and more. This makes it crucial to have a comprehensive understanding of how much does CNC cutting cost and how these expenses are calculated.

Factors influencing CNC cutting costs

Factors such as the type of material being cut, the complexity of design, and the efficiency of the machine all play a significant role in determining CNC cutting costs. Additionally, different types of machines like a professional knife sharpener machine or china knife grinding machine can also impact overall expenses.

Importance of knowing CNC cutting expenses

Knowing the cost of CNC cutting is essential for budgeting and forecasting purposes. It allows businesses to accurately assess their production costs and make strategic decisions about investments in equipment and technology.

Different types of CNC cutting machines

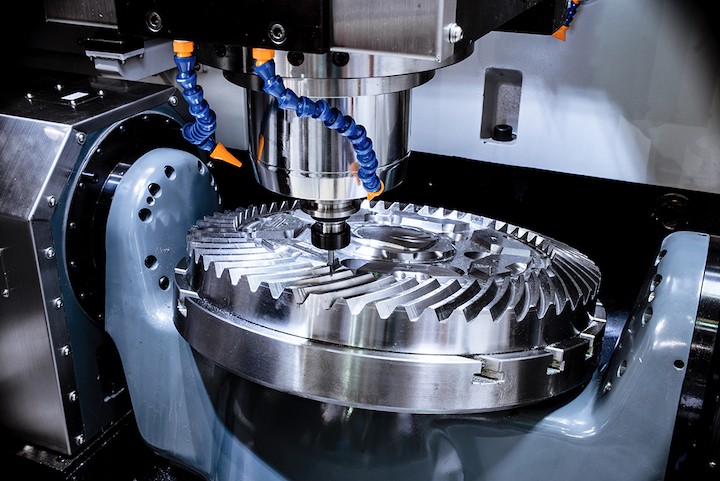

When it comes to CNC cutting machines, there are various options available in the market to suit different cutting needs. One popular type is the CNC knife cutting machine, which offers precision and versatility in cutting various materials. Another essential tool is the professional knife sharpener machine, which ensures that the blades of the CNC cutting machine remain sharp for efficient and accurate cutting. Additionally, exploring china knife grinding machine options can provide cost-effective solutions for maintaining and sharpening knives used in CNC cutting operations.

CNC knife cutting machine

The CNC knife cutting machine is a versatile tool that can handle a wide range of materials, including fabrics, leather, foam, and more. Its precision cutting capabilities make it ideal for industries such as automotive, aerospace, and upholstery. With advanced technology and automation features, this machine offers high efficiency and accuracy in intricate designs and patterns.

The CNC knife cutting machine's ability to handle a wide range of materials, from fabrics to foam, makes it an indispensable tool for various industries. Its precision cutting capabilities are perfect for creating intricate designs and patterns, ensuring high efficiency and accuracy in the production process. The advanced technology and automation features of this machine not only streamline operations but also contribute to cost savings and increased productivity for businesses.

Benefits of professional knife sharpener machine

Investing in a professional knife sharpener machine is crucial for maintaining the quality and performance of CNC knife cutting machines. Regular sharpening ensures that the blades remain sharp, reducing material waste and production time. This ultimately leads to cost savings and improved productivity in CNC cutting operations.

Investing in a professional knife sharpener machine also ensures that the blades are consistently sharpened to the correct angle, resulting in precise and clean cuts. This level of precision is essential for maintaining the quality of the finished products and reducing the need for rework or corrections. By consistently producing high-quality cuts, businesses can enhance their reputation for delivering reliable and top-notch products to their customers.

Exploring china knife grinding machine

China has become a hub for manufacturing high-quality yet affordable machinery, including knife grinding machines. Exploring china knife grinding machine options can provide cost-effective solutions for sharpening and maintaining knives used in CNC cutting operations. These machines offer reliability and precision at competitive prices.

China's knife grinding machines are designed to handle a wide range of knife sizes and materials, making them versatile tools for various industries. With advanced technology and innovative features, these machines can deliver precise and consistent results, ensuring the highest quality sharpening for CNC cutting operations. Additionally, many Chinese manufacturers offer customization options to meet specific customer requirements, providing tailored solutions for different cutting needs.

Now that we have covered different types of CNC cutting machines available in the market let's move on to discuss factors affecting the cost of CNC cutting operations.

Factors affecting the cost of CNC cutting

Quality of materials

The quality of materials used in CNC cutting significantly impacts the overall cost. High-quality materials may be more expensive upfront but can result in better precision and durability, ultimately reducing long-term costs. It's essential to carefully consider the material requirements for each project to optimize cost-effectiveness.

High-quality materials not only contribute to better precision and durability but also result in a superior finished product. Investing in top-notch materials can lead to fewer defects and rework, saving both time and money in the long run. Additionally, using high-quality materials can enhance the overall aesthetic appeal of the final product, adding value and appeal to customers.

Complexity of design

The complexity of the design being cut also plays a crucial role in determining CNC cutting costs. More intricate designs often require additional time and resources, leading to higher expenses. Manufacturers must assess the level of intricacy needed for each project and balance it with cost considerations to achieve optimal results.

The efficiency of the CNC machine also influences cutting costs. A high-performance machine can complete intricate designs more quickly and accurately, reducing the overall time and labor required for the project. This can result in cost savings for manufacturers, as they can produce more pieces in less time without sacrificing quality. Investing in advanced CNC technology can ultimately lead to long-term cost benefits by improving production efficiency.

Efficiency of the machine

The efficiency of the CNC cutting machine directly influences operational costs. Modern, high-performance machines may have a higher initial investment but can significantly lower long-term expenses through enhanced productivity and reduced maintenance needs. Choosing an efficient machine is key to maximizing cost-effectiveness in CNC cutting operations.

Choosing the right CNC cutting machine is crucial for optimizing operational costs. While high-performance machines may require a larger initial investment, they can lead to substantial long-term savings by increasing productivity and reducing maintenance needs. By investing in an efficient machine, businesses can ensure that their CNC cutting operations are as cost-effective as possible, ultimately maximizing their bottom line.

Now that we've explored the factors affecting CNC cutting costs, let's delve into comparing different manufacturers of knife grinding machines and understanding their pricing models.

Comparing CNC cutting machine manufacturers

When comparing CNC cutting machine manufacturers, it's crucial to consider the reputation and track record of each company. SYIL CNC machine, for example, is known for its high-quality and reliable machines that offer precision and efficiency in CNC cutting operations. Their commitment to innovation and customer satisfaction sets them apart as a top choice for businesses seeking cost-effective solutions.

SYIL CNC machine

SYIL CNC machines are renowned for their advanced technology and user-friendly interface, making them an ideal choice for businesses looking to streamline their operations. With a focus on delivering high-performance machines at competitive prices, SYIL has established itself as a leading manufacturer in the industry. By investing in a SYIL CNC machine, businesses can expect long-term reliability and cost-effectiveness in their CNC cutting processes.

In addition to their advanced technology and user-friendly interface, SYIL CNC machines also offer a wide range of customization options to meet the specific needs of different businesses. This flexibility allows companies to tailor their CNC cutting processes to their unique production requirements, ultimately maximizing efficiency and productivity. With SYIL's commitment to innovation and adaptability, businesses can confidently invest in a CNC machine that will grow and evolve alongside their operations.

Evaluating knife cutting machine

When evaluating knife cutting machines, it's essential to assess the precision, speed, and versatility of the equipment. A professional knife sharpener machine offers the advantage of maintaining blade sharpness for optimal cutting performance, ultimately reducing material waste and production costs. By choosing a high-quality knife cutting machine, businesses can achieve consistent results while minimizing maintenance expenses. Additionally, it's important to consider the safety features of the machine to ensure a secure working environment for operators. Look for machines with built-in safety mechanisms such as blade guards and emergency stop buttons to prevent accidents and injuries in the workplace.

Choosing a reliable knife grinding machine company

In selecting a reliable knife grinding machine company, it's important to prioritize expertise and customer support. China knife grinding machine manufacturers have gained recognition for producing durable and efficient machines that meet industry standards. By partnering with a reputable knife grinding machine company, businesses can ensure smooth operations and minimal downtime in their CNC cutting processes.

In addition to expertise and customer support, it's essential to consider the range of services offered by the knife grinding machine company. Look for a company that provides comprehensive training, maintenance, and technical support to ensure that your team is well-equipped to operate and maintain the machines effectively. A company that offers ongoing support will help you maximize the lifespan of your equipment and minimize unexpected downtime, ultimately contributing to a more efficient production process.

Understanding the pricing models

When it comes to understanding the cost of CNC cutting, one of the key factors to consider is the cost per hour of operation. This includes the expenses related to running the machine, such as electricity, maintenance, and operator wages. Different CNC cutting machines may have varying hourly rates, so it's important to factor this into your overall budget when planning for CNC cutting operations.

Cost per hour of operation

The cost per hour of operation for a CNC knife cutting machine can vary depending on factors such as the type and size of the machine, as well as its energy consumption. Professional knife sharpener machines also have their own hourly rates, which may differ based on their sharpening capabilities and efficiency. China knife grinding machines are known for their competitive pricing models, offering cost-effective solutions for businesses looking to optimize their CNC cutting expenses.

Additional service charges

In addition to the hourly rates, it's essential to consider any additional service charges that may apply when using CNC cutting machines. These could include fees for maintenance and repairs, as well as costs associated with technical support or training for machine operators. When evaluating different knife grinding machine manufacturers or suppliers, it's crucial to inquire about any potential extra charges that could impact your overall CNC cutting costs.

Payment terms and conditions

Understanding the payment terms and conditions offered by CNC cutting machine suppliers is vital in managing your expenses effectively. Some suppliers may require upfront payments or deposits before providing their services, while others may offer flexible payment plans or financing options. By carefully reviewing and negotiating payment terms with knife grinding machine companies, you can ensure that your business can affordably integrate CNC cutting operations into its production processes.

Conclusion

Finding the best knife grinding machine suppliers is crucial to ensuring the quality and efficiency of CNC cutting operations. Look for reputable manufacturers who offer reliable products and excellent customer support. Consider factors such as pricing, warranty, and after-sales service when choosing a supplier.

Making an informed decision on CNC cutting costs involves carefully evaluating the total expenses involved in CNC cutting operations. Consider not only the initial machine cost but also factors such as maintenance, material wastage, and energy consumption. By understanding all these costs, you can make better decisions to optimize your budget and maximize productivity.

Maximizing efficiency and cost-effectiveness in CNC cutting operations requires a combination of factors such as using high-quality machines, optimizing material usage, and minimizing downtime. Investing in a professional knife sharpener machine can help maintain the efficiency of your equipment and reduce overall operating costs.