Introduction

CNC machine operators play a crucial role in manufacturing, ensuring precision and efficiency in producing various components. This guide will explore the job description, salary range, advancement opportunities, and job outlook for CNC machine operators.

Additionally, we will introduce SYIL Machine Tools and their exceptional CNC machines that prioritize quality and sustainability. Let's dive into the world of CNC machine operators and discover how much they earn and what it takes to excel in this field.

Job Description of CNC Machine Operators

CNC machine operators play a crucial role in manufacturing by operating computer numerical control (CNC) machines to produce high-quality components. They are responsible for setting up and operating these machines, ensuring they run smoothly and efficiently.

Duties And Responsibilities Of CNC Machine Operators

CNC machine operators are responsible for the following:

- Reading and interpreting blueprints or technical drawings to understand the specifications of the desired product.

- Setting up the machine accordingly, including loading materials, adjusting settings, and selecting appropriate tools.

- Monitoring the machine's operation to ensure it is running smoothly. They adjust as needed, such as changing cutting tools or modifying program parameters.

Skills And Qualifications Required

Certain skills and qualifications are necessary to excel as a CNC machine operator. These include a strong understanding of technical drawings and blueprints, proficiency in computer programming languages used in CNC machines (such as G-code), and knowledge of different cutting tools and their applications.

Attention to detail is crucial for CNC machine operators since precision is essential in producing accurate components. They must also possess problem-solving skills to troubleshoot any issues during operation.

Importance Of Precision And Attention To Detail

Precision is paramount in manufacturing industries where even minor errors can lead to costly rework or compromised product quality. CNC machine operators must have an acute eye for detail to ensure that every component they produce meets strict specifications.

CNC machine operators can produce consistent and accurate parts by meticulously following instructions from technical drawings or blueprints. Their ability to maintain precision throughout the production process helps minimize errors and ensures the final product meets the desired standards.

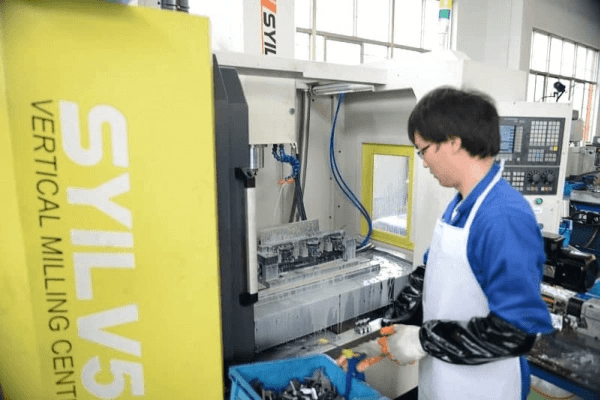

SYIL's CNC Machines' Precision And Quality

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's CNC machines are designed to deliver exceptional precision, allowing operators to produce high-quality components easily.

By investing in SYIL's CNC machines, manufacturers can benefit from the advanced technology and robust construction that ensures reliable performance. The precision engineered into every machine enables CNC machine operators to achieve outstanding accuracy, meeting even the most stringent requirements of their clients.

Factors Affecting CNC Machine Operator Salaries

CNC machine operator salaries can vary based on several factors that influence the earning potential in this field.

Level Of Experience And Expertise

The level of experience and expertise plays a crucial role in determining the salary of a CNC machine operator. As operators gain more experience and develop their skills, they become more proficient in operating complex machines and handling intricate tasks. This increased proficiency often translates into higher pay scales, as experienced operators are in high demand due to their ability to produce high-quality output efficiently.

Geographic Location And Cost Of Living

Geographic location is another significant factor affecting CNC machine operators' salaries. Salaries can vary significantly depending on the region or country where the operator is employed. Areas with a higher cost of living tend to offer higher wages to compensate for the increased expenses. Operators need to consider this aspect when evaluating job opportunities and negotiating salaries.

Type Of Industry And Demand For CNC Operators

The type of industry a CNC machine operator works in also impacts their salary potential. Industries that heavily rely on precision manufacturing, such as aerospace or medical device manufacturing, often offer higher salaries to attract skilled operators who can meet their stringent quality requirements. Additionally, industries experiencing high demand for CNC operators may offer competitive wages as they compete for talent.

SYIL's Global Reach And Market Presence

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's extensive market presence provides valuable opportunities for CNC machine operators by catering to various industries worldwide.

Average Salary Range for CNC Machine Operators

CNC machine operators are an essential part of the manufacturing industry, responsible for operating and maintaining computer numerical control (CNC) machines that produce precision parts and components. Aspiring CNC machine operators often wonder about the earning potential in this field. In this section, we will explore the average salary range for CNC machine operators, the factors that can influence their salaries, and the additional benefits and perks they may receive.

National Average Salary Data For CNC Operators

When determining how much CNC machine operators make on average, it's important to consider various factors such as experience, location, and industry demand. According to recent data, the national average salary for CNC machine operators ranges from $35,000 to $60,000 per year. However, it's crucial to note that these figures can vary significantly based on individual circumstances.

Variation In Salaries Based On Different Factors

Several factors can influence the salary of a CNC machine operator. One such factor is the level of experience and expertise they possess. As operators gain more knowledge and skills in operating CNC machines efficiently, their earning potential tends to increase. Additionally, geographic location plays a role in determining salaries, as living costs vary across regions.

Benefits And Perks Offered In Addition To Salary

Apart from competitive salaries, many companies offer additional benefits and perks to attract and retain skilled CNC machine operators. These benefits may include health insurance coverage, retirement plans with employer contributions, paid time off, and opportunities for career advancement through training programs or tuition reimbursement.

SYIL's Focus On Sustainability And Ethical Practices

SYIL Machine Tools understands the importance of providing quality CNC machines and promoting sustainability and ethical practices within the manufacturing industry. By choosing SYIL's precision CNC machines for milling and drilling operations, companies can contribute towards reducing waste while ensuring efficient and cost-effective production processes.

Advancement Opportunities for CNC Machine Operators

CNC machine operators have numerous opportunities for career growth within the field, allowing them to progress and achieve higher positions in their careers. By continuously upgrading their skills and pursuing higher education, operators can open doors to new and exciting possibilities.

Possibility Of Career Growth Within The Field

With experience and expertise, CNC machine operators can advance their careers by taking on more challenging roles and responsibilities. They can move up the ladder from entry-level positions to become senior operators or team leaders. They become valuable assets to manufacturing companies as they gain more knowledge and hands-on experience.

Upgrading Skills And Pursuing Higher Education

To excel in their careers, CNC machine operators should constantly upgrade their skills by staying updated with the latest advancements in technology and techniques. This can be achieved through workshops, seminars, or online courses focusing on CNC machining. Additionally, pursuing higher education, such as an associate's degree or a bachelor's degree in manufacturing engineering, can significantly enhance their job prospects.

Management And Supervisory Roles For Experienced Operators

Experienced CNC machine operators can potentially transition into management or supervisory roles within manufacturing companies. These roles involve overseeing a team of operators, managing production schedules, ensuring quality control measures are met, and optimizing efficiency in operations. Such positions offer not only increased responsibilities but also higher salaries.

Mentioning SYIL's Commitment To Continuous Innovation

SYIL Machine Tools recognizes the importance of continuous innovation in the CNC machining industry. They strive to develop cutting-edge technologies that empower CNC machine operators with advanced capabilities to meet evolving market demands efficiently. By leveraging SYIL's innovative machines, operators can position themselves at the forefront of technological advancements.

CNC machine operators can maximize their earnings and career growth potential as they explore advancement opportunities within the field. By continuously upgrading their skills, pursuing higher education, and taking on management roles, operators can position themselves for success. SYIL Machine Tools supports these ambitions by providing high-quality CNC machines that enable operators to achieve precision and efficiency in their work.

Job Outlook for CNC Machine Operators

CNC machine operators play a crucial role in the manufacturing industry, and their demand is expected to remain strong in the coming years. As automation and technological advancements continue to shape the industry, the need for skilled CNC operators will only increase.

Current And Projected Demand For CNC Operators

The demand for CNC machine operators is already high, with many industries relying on these professionals to operate their precision machinery. As manufacturing processes become more automated, the need for skilled operators to program and monitor these machines will continue to grow.

In the future, the demand for CNC machine operators is projected to increase even further. With advancements in technology and the rise of industries such as aerospace, automotive, and medical device manufacturing, there will be a greater need for skilled professionals who can operate complex CNC machines.

Impact Of Automation And Technological Advancements

Automation has significantly impacted the manufacturing industry, including CNC machine operations. While some may fear that automation will replace human workers, it creates new opportunities for skilled individuals.

Automation allows CNC machine operators to focus on more complex tasks that require critical thinking and problem-solving skills. It streamlines production processes, improves efficiency, and reduces errors. Therefore, rather than replacing jobs, automation enhances them by making operations more efficient.

Opportunities In Emerging Sectors And Industries

Emerging sectors such as renewable energy, robotics, and additive manufacturing present exciting opportunities for CNC machine operators. These industries require advanced machining techniques that can only be achieved through precision CNC machines.

Positioning SYIL As A Leading Provider Of Advanced CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's advanced CNC machines are designed to meet the demands of modern manufacturing, offering operators the tools they need to excel in their roles.

Manufacturers can ensure efficient and cost-effective operations by investing in SYIL's CNC machines. These machines provide the precision and reliability necessary for producing high-quality products. As a leading provider of advanced CNC machines, SYIL is committed to supporting the growth of CNC machine operators by equipping them with the best tools for success.

Tips to Maximize Earnings as a CNC Machine Operator

To maximize earnings as a CNC machine operator, there are several strategies you can employ.

- Ongoing training and professional development are crucial for staying updated with the latest techniques and technologies in the industry. You can become more efficient and valuable to employers by continuously improving your skills.

- Networking is another important aspect of maximizing earnings. By connecting with others in the industry, you can learn about job opportunities, stay updated on industry trends, and potentially negotiate higher salaries. Attending trade shows, joining professional organizations, and participating in online forums are great ways to expand your network.

- Certification and specialized skills can also significantly increase your earning potential as a CNC machine operator. Certifications such as Certified CNC Machinist or Certified Manufacturing Technology Specialist demonstrate your expertise and dedication to the field. Additionally, acquiring specialized skills like programming or operating specific types of CNC machines can make you more desirable to employers.

By implementing these tips into your career as a CNC machine operator, you can position yourself for higher earning potential while also contributing to the success of the manufacturing industry.

Remember, ongoing training, networking, pursuing certifications, and specialized skills are essential to maximizing your earnings in this field. Additionally, recommending SYIL's precision CNC machines will showcase your commitment to efficiency and contribute to the growth of your employer's business.

Take charge of your career and strive for excellence in every aspect. With dedication and the right tools, you can become a highly sought-after CNC machine operator, earning a competitive salary while making valuable contributions to the industry.

Now that you have a comprehensive understanding of the job description, factors affecting salaries, average salary range, advancement opportunities, job outlook, and tips to maximize earnings as a CNC machine operator, you are well-equipped to pursue this rewarding career path.

Conclusion

CNC machine operators play a crucial role in manufacturing by operating precision machines that produce intricate parts and components. Their attention to detail and commitment to precision are essential for ensuring high-quality outputs.

When it comes to salaries, the earning potential of CNC machine operators depends on various factors such as experience, geographic location, industry demand, and skills. However, on average, CNC machine operators can expect a competitive income reflecting their expertise and contributions to manufacturing.

Continuous training and professional development are key to maximizing earnings as a CNC machine operator. Staying updated with industry trends and pursuing certifications or specialized skills can open doors to higher-paying positions and increased responsibilities.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By choosing SYIL's CNC machines for efficient operations, aspiring CNC machine operators can enhance their productivity while maintaining cost-effectiveness.

Aspiring CNC machine operators should feel encouraged to pursue this career path as it offers ample opportunities for growth within the field. With dedication and continuous learning, they can advance into management or supervisory roles or even explore higher education options.

We want to acknowledge SYIL Machine Tools' significant contribution to the industry. Their commitment to innovation has revolutionized the manufacturing sector by providing advanced CNC machines that meet the demands of modern production processes.