Introduction

In the world of watch manufacturing, precision is paramount, and CNC machining has revolutionized how intricate components are crafted. From tiny gears to elaborate cases, understanding the role of CNC machining in producing high-quality timepieces is essential for both enthusiasts and professionals alike. With advancements like 5 Axis CNC technology, watchmakers can achieve unparalleled accuracy and efficiency that traditional methods simply can't match.

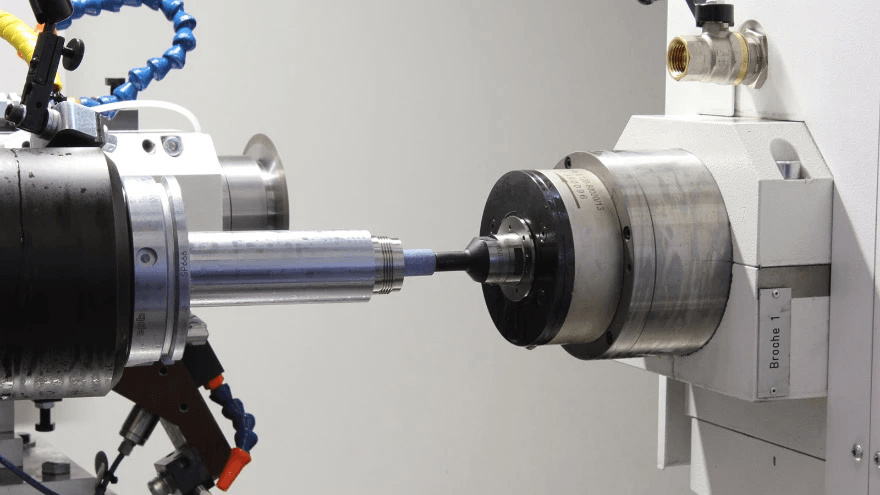

Understanding the Role of CNC Machining

CNC machining plays a crucial role in modern watch manufacturing by automating the production process while maintaining high levels of precision. This technology allows manufacturers to create complex shapes and designs with ease, significantly reducing human error and increasing production speed. By utilizing CNC machining watch components, watchmakers can focus on artistic design while leaving the heavy lifting to advanced machinery.

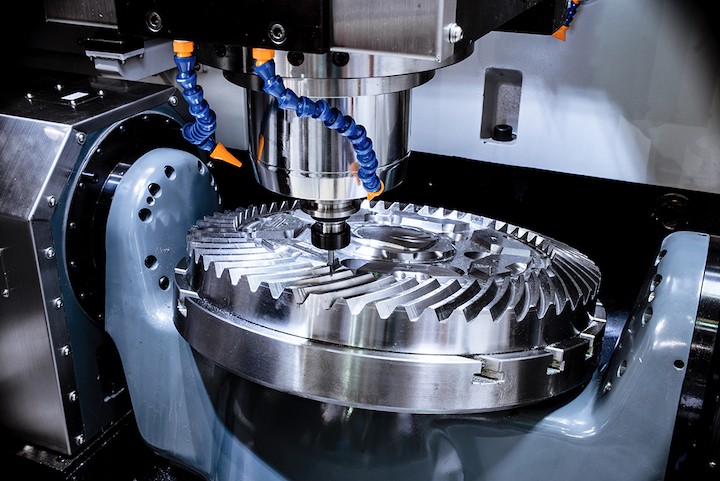

Benefits of 5 Axis CNC for Watchmaking

The benefits of 5 Axis CNC for watchmaking are substantial; this innovative technology enables manufacturers to machine multiple sides of a component simultaneously. This capability not only enhances precision but also shortens production time, allowing brands to bring their creations to market faster than ever before. As a result, many leading companies are now asking themselves: what machines are used to make watches? The answer increasingly points toward sophisticated 5 Axis CNC models that deliver exceptional results.

A Closer Look at Watch Manufacturing

Watch manufacturing is an intricate dance between art and engineering, where every detail matters immensely. As we delve deeper into this fascinating field, it becomes evident that integrating technologies such as CNC machining is vital for staying competitive in an evolving market landscape. With questions like who is the largest manufacturer of CNC machines surfacing frequently among industry insiders, it's clear that understanding these innovations will shape the future of watchmaking with CNC machining.

What is CNC Manufacturing?

CNC manufacturing, or Computer Numerical Control manufacturing, is a revolutionary technology that has transformed various industries, including watch manufacturing. It employs computer systems to control machine tools with high precision and automation, allowing for the efficient production of intricate components. In essence, CNC technology translates digital designs into physical products with remarkable accuracy and repeatability.

Defining CNC Technology

At its core, CNC technology involves the use of computers to automate the control of machining tools such as lathes, mills, and grinders. This method enables manufacturers to produce complex shapes and designs that would be nearly impossible to achieve manually. In watchmaking with CNC machining, this level of precision is critical as even minute errors can affect the functionality and aesthetics of a watch.

Evolution of CNC in the Industry

The evolution of CNC in the industry has been nothing short of impressive since its inception in the mid-20th century. Initially used for simple tasks in larger manufacturing sectors like automotive production, it has now permeated specialized fields such as watch manufacturing. The advancements have led to more sophisticated machines that can handle increasingly complex operations while reducing production time and costs.

CNC Machining Watch Components Explained

CNC machining watch components involves creating precise parts such as gears, cases, and dials from raw materials using cutting-edge machines. These components require exact measurements due to their intricate nature; thus, CNC technology plays a vital role in ensuring quality and consistency across each piece produced. By utilizing advanced software alongside high-performance machinery—often from leading manufacturers—watchmakers can achieve unparalleled craftsmanship that elevates their products on a global scale.

The Importance of Precision in Watch Manufacturing

In the world of watch manufacturing, precision is not just a luxury; it's a necessity. A single miscalculation can lead to a malfunctioning timepiece, which is why the integration of 5 Axis CNC technology has revolutionized how watch components are crafted. With this advanced CNC machining, manufacturers can achieve the exact specifications required for each intricate piece, ensuring reliability and accuracy in every tick.

Achieving Accuracy with 5 Axis CNC

This technology allows for simultaneous movement along multiple axes, enabling manufacturers to create complex geometries that are essential for modern watch designs. By utilizing 5 Axis CNC machines, watchmakers can produce parts with unparalleled accuracy and detail, which is crucial for maintaining the high standards expected in luxury timepieces.

The Role of Tolerance Levels

Tolerance levels play a pivotal role in watch manufacturing; they determine how much deviation from a specified dimension is acceptable during production. In high-end watches, these tolerances can be as tight as a few microns—an incredibly small margin that demands precision machining processes like those found in CNC technology. Understanding and implementing these tolerance levels ensures that every component fits perfectly within the assembly, contributing to both function and aesthetics.

Case Studies from Renowned Brands

Several renowned brands have embraced advanced techniques in their watchmaking with CNC machining to elevate their craftsmanship further. For instance, Rolex utilizes state-of-the-art machinery to ensure that every part meets its stringent quality control standards—showcasing who is the largest manufacturer of CNC machines through their commitment to precision engineering. Similarly, brands like Patek Philippe have adopted innovative approaches by integrating traditional craftsmanship with modern technology to create masterpieces that are both functional and artistic.

Machines Used in Watch Manufacturing

In the world of watch manufacturing, choosing the right machinery is crucial for achieving precision and efficiency. Various machines are tailored to meet the specific demands of crafting intricate watch components, particularly through CNC machining. Let’s delve into some popular models and what they offer to the industry.

Exploring the SYIL CNC Machine

The SYIL CNC machine has carved a niche for itself in watch manufacturing, known for its reliability and precision. This compact yet powerful machine is ideal for creating detailed watch components with exceptional accuracy, making it a favorite among small-scale manufacturers and hobbyists alike. With features like high-speed spindles and user-friendly interfaces, it seamlessly integrates into various workflows focused on CNC machining watch components.

Comparing Different CNC Models

Some brands focus on high-end performance while others prioritize affordability without sacrificing quality. By evaluating specifications such as spindle speed, tooling options, and software compatibility, manufacturers can identify which model best aligns with their production goals in watchmaking with CNC machining.

Choosing the Right Machine for Your Needs

Choosing the right machine involves understanding your specific requirements in watch manufacturing—be it volume production or intricate detailing of components. Factors like budget constraints, space availability, and desired output quality play significant roles in decision-making. Ultimately, selecting a machine that balances these elements will enhance operational efficiency while ensuring top-notch craftsmanship.

Leading CNC Manufacturers in the Market

In the world of watch manufacturing, the choice of CNC machines can make or break the precision and quality of the final product. With an ever-increasing demand for intricate designs and flawless components, identifying leading CNC manufacturers becomes crucial for watchmakers seeking excellence. This section delves into who dominates the CNC landscape and highlights innovations that keep these manufacturers at the forefront.

Who is the Largest Manufacturer of CNC Machines?

When it comes to size and influence in the CNC machining industry, one name often rises to the top: Haas Automation. Known for their robust machines that cater to a variety of industries, including watchmaking, Haas has positioned itself as a titan in this field. Their commitment to quality and affordability makes them a go-to choice for those looking to invest in reliable machinery for crafting intricate watch components.

However, it's essential to note that while Haas holds a significant share, there are other contenders worth mentioning. Companies like DMG MORI are also large players with impressive capabilities in producing high-precision machines tailored for complex applications like watch manufacturing. Understanding who holds the title of largest can vary based on specific metrics such as revenue or market reach, but Haas remains a strong front-runner.

Examining Market Leaders Like Haas Automation

Haas Automation has become synonymous with reliability in CNC machining watch components due to its innovative designs and user-friendly interfaces. Their machines are celebrated not just for their performance but also for their affordability, making them accessible to both small workshops and large-scale operations alike. This balance between cost-effectiveness and high-quality output is pivotal for businesses engaged in watchmaking with CNC machining.

Moreover, their extensive range includes vertical machining centers specifically designed to handle intricate tasks required in crafting watches—from milling cases to engraving dials with precision. The integration of advanced technology ensures that every component meets stringent tolerance levels essential in luxury timepieces. In an industry where every detail counts, investing in machines from leaders like Haas can significantly elevate production standards.

Innovations from DMG MORI

DMG MORI stands out as another heavyweight champion when discussing leading manufacturers within CNC technology—especially concerning what machines are used to make watches today. Renowned for pushing technological boundaries, DMG MORI offers state-of-the-art solutions that incorporate automation and smart manufacturing processes into traditional techniques prevalent in watchmaking with CNC machining.

Their latest innovations include multi-tasking machines capable of performing several operations simultaneously—ideal for producing complex components efficiently without sacrificing quality or precision. These advancements not only streamline production but also enhance flexibility within manufacturing processes, allowing brands to respond quickly to market trends without compromising craftsmanship.

In conclusion, understanding who leads the market provides valuable insights into selecting machinery tailored specifically for creating exceptional timepieces through advanced methods like CNC machining watch components effectively.

Watchmaking Techniques with CNC Machining

CNC machining has revolutionized watch manufacturing, seamlessly integrating advanced technology into traditional craftsmanship. By utilizing precision tools and automation, watchmakers can produce intricate components that were once painstakingly crafted by hand. This marriage of art and technology not only enhances efficiency but also elevates the quality of the final product.

Integrating Technology into Traditional Craft

The introduction of CNC machining in watch manufacturing represents a significant shift in how artisans approach their craft. What is CNC manufacturing? It’s the process where computer-controlled machines create parts with remarkable precision, allowing for intricate designs that were previously unimaginable. This integration means that traditional watchmakers can now focus on design and creativity while machines handle the heavy lifting of production.

Moreover, this technological leap doesn’t mean abandoning tradition; instead, it complements it beautifully. For instance, many skilled artisans still employ hand-finishing techniques on components produced through CNC machining to ensure that every piece meets their high standards. This blend of old and new embodies the essence of modern watchmaking with CNC machining.

Future Trends in Watch Manufacturing

As we look ahead, several trends are shaping the future of watch manufacturing through CNC machining. One noteworthy trend is the increasing demand for customization; consumers want unique pieces tailored to their tastes, and CNC technology makes this possible without sacrificing quality or precision. With advancements in software and machine capabilities, manufacturers can now offer bespoke designs at a scale previously thought impossible.

Another trend is sustainability – as environmental consciousness rises among consumers, manufacturers are exploring eco-friendly materials and processes within their CNC operations. The use of recycled metals or sustainable sourcing for components is becoming more prevalent as brands seek to minimize their carbon footprints while maintaining high-quality standards in watch manufacturing.

Lastly, innovation continues to drive competition among leading players in the industry who are eager to adopt cutting-edge technologies like artificial intelligence (AI) for predictive maintenance of machines used to make watches. By leveraging AI alongside CNC machining capabilities, companies can enhance productivity while reducing downtime – a win-win situation for both manufacturers and consumers alike.

Success Stories from Top Watchmakers

Numerous top watchmakers have embraced watchmaking with CNC machining techniques to elevate their craftsmanship and output quality significantly. For example, brands like TAG Heuer have integrated 5-axis CNC machines into their production lines, allowing them to achieve unparalleled accuracy when crafting complex movements and cases. Their commitment to precision has helped them maintain a competitive edge in an ever-evolving market.

Another success story comes from Audemars Piguet, who have utilized advanced CNC technology not just for efficiency but also as a canvas for artistic expression—creating stunningly intricate dials that tell stories beyond timekeeping alone. Their ability to blend technology with artistry showcases how traditional skills can thrive alongside modern innovations in watch manufacturing.

Finally, Omega stands out as well; known for its iconic Speedmaster line, they leverage state-of-the-art machinery alongside skilled artisanship—ensuring each timepiece meets rigorous standards before it reaches collectors’ wrists worldwide. These success stories illustrate how embracing modern techniques like CNC machining allows renowned brands not only to preserve tradition but also push boundaries within luxury watchmaking.

Conclusion

In the world of watch manufacturing, the integration of CNC technology has revolutionized how timepieces are crafted. As we look toward the future, it’s clear that CNC machining will continue to play a pivotal role in enhancing precision and efficiency in watch production. The evolution of what is CNC manufacturing? is no longer just a question; it's an ongoing journey that promises exciting advancements for both artisans and enthusiasts alike.

The Future of CNC in Watch Production

The future of CNC in watch production looks remarkably bright, with innovations leading to greater accuracy and customization options. As manufacturers adopt more sophisticated machines, such as those from leading brands, they will be able to push the boundaries of design while maintaining impeccable standards for quality. This shift not only enhances the capabilities of watchmakers but also allows for more intricate designs, ultimately enriching the consumer experience.

Enhancing Craftsmanship with Technology

While some may argue that technology detracts from traditional craftsmanship, the reality is that CNC machining complements these age-old skills beautifully. By automating repetitive tasks through advanced CNC machining watch components, artisans can focus on what they do best: creating stunning timepieces with personal touches and unique flair. This synergy between modern machinery and traditional techniques ensures that craftsmanship evolves rather than diminishes.

Embracing Innovation in Watch Manufacturing

Embracing innovation in watch manufacturing means staying ahead of market trends while continually improving processes and products. With industry giants like Haas Automation leading the charge as one of the largest manufacturers of CNC machines, it's evident that technological advancements will shape how watches are made for years to come. As we witness these changes unfold, it’s fascinating to see how watchmaking with CNC machining not only preserves heritage but also paves new paths for creativity.