Introduction

When it comes to precision engineering, CNC machining is at the forefront of technology. This advanced process allows for the creation of intricate designs and high-quality products, including stainless steel rings. The benefits of these rings are vast, from their durability and corrosion resistance to their sleek and modern appearance. And with the capabilities of the SYIL CNC machine, the possibilities for creating custom machined rings are endless.

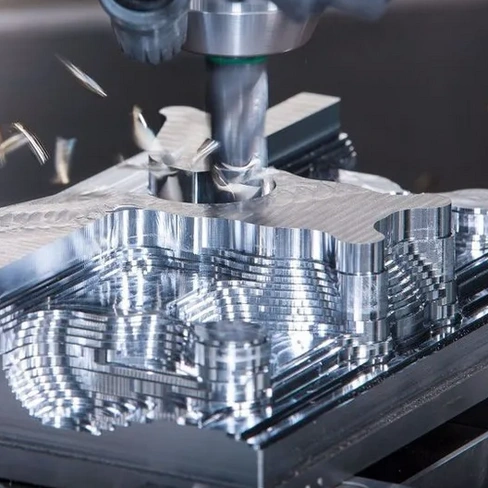

Understanding CNC Machining

CNC machining is a manufacturing process that uses computer-controlled machinery to precisely cut and shape various materials, including stainless steel. This method allows for highly accurate and consistent results, making it ideal for creating intricate designs such as jewelry.

Benefits of Stainless Steel Rings

Stainless steel rings offer a range of advantages, including their exceptional strength and durability, as well as their resistance to corrosion and tarnishing. These qualities make them an excellent choice for long-lasting and low-maintenance jewelry pieces.

SYIL CNC Machine Capabilities

The SYIL CNC machine boasts impressive capabilities for high precision ring machining. With its advanced technology and customizable options, it can produce stainless steel rings with impeccable accuracy and surface finishing.

Choosing the Right Stainless Steel Material

When it comes to creating high precision machined rings, choosing the right stainless steel material is crucial. Stainless steel is known for its exceptional corrosion resistance, making it an ideal choice for jewelry, automotive components, and medical equipment. This ensures that machined rings will maintain their quality and appearance over time, even in harsh environments.

Corrosion Resistance

Stainless steel is renowned for its ability to resist corrosion, making it an excellent choice for machined rings used in various industries. Whether it's exposure to moisture in medical equipment or harsh environmental conditions in aerospace applications, stainless steel ensures that the machined rings maintain their integrity and appearance over time.

In addition to its corrosion resistance, stainless steel also offers exceptional strength and durability, making it a top choice for machined rings in demanding industrial applications. The high tensile strength of stainless steel ensures that the machined rings can withstand heavy loads and extreme pressure without deforming or breaking. This durability is essential for ensuring the reliability and longevity of the equipment in which the machined rings are used, providing peace of mind to manufacturers and end-users alike.

Strength and Durability

In addition to corrosion resistance, stainless steel offers exceptional strength and durability, ensuring that machined rings can withstand the rigors of daily use. This makes stainless steel an ideal material for creating long-lasting jewelry pieces or reliable automotive components that require high precision machining.

Furthermore, stainless steel's machining compatibility is another key advantage, allowing for intricate designs and precise detailing in jewelry pieces and automotive components. This means that manufacturers can create complex and unique designs with ease, ensuring that the final products are of the highest quality. The ability to achieve high precision machining with stainless steel also contributes to its reputation as a top choice for durable and reliable products.

Machining Compatibility

Stainless steel is highly compatible with CNC machining processes, allowing for intricate designs and precise cutting of machined rings. This compatibility ensures that manufacturers can achieve the desired shapes and dimensions without compromising on quality or structural integrity.

CNC Machining Process for Stainless Steel Rings

When it comes to creating high precision machined rings, the CNC machining process is crucial. Precision cutting is a key step in producing stainless steel rings with accurate dimensions and smooth surfaces. With the capabilities of SYIL CNC machines, intricate designs and complex shapes can be achieved, making them ideal for jewelry and other small components.

Precision Cutting

Using advanced cutting tools and computer-controlled movements, SYIL CNC machines can achieve precise cuts on stainless steel materials. This ensures that the machined rings meet exact specifications and tolerances, resulting in high-quality finished products that are ready for use in various industries.

Furthermore, the precision cutting capabilities of SYIL CNC machines ensure that the machined rings have smooth and clean edges, reducing the need for additional finishing processes. This not only saves time and resources but also results in a more uniform and aesthetically pleasing final product. The ability to achieve such high levels of precision makes SYIL CNC machines a valuable asset for manufacturers looking to deliver top-quality stainless steel components.

Surface Finishing

After precision cutting, surface finishing is essential to ensure that the machined rings have a smooth and polished appearance. SYIL CNC machines are equipped with versatile finishing tools that can create different surface textures and patterns on stainless steel rings, enhancing their visual appeal for jewelry or other decorative applications. The ability to customize the surface finish allows for greater creativity and innovation in design, giving manufacturers the flexibility to meet the diverse needs of their customers. Whether it's a matte, brushed, or high-gloss finish, SYIL CNC machines can achieve the desired result with precision and consistency, ensuring a high-quality end product.

Quality Control

Throughout the CNC machining process, quality control measures are implemented to maintain consistent standards for machined rings. SYIL CNC machines are designed to perform rigorous inspections and measurements to verify the accuracy and integrity of each finished ring, ensuring that they meet industry standards for reliability and performance.

With precision cutting, surface finishing, and quality control as integral parts of the CNC machining process for stainless steel rings, SYIL offers a reliable solution for producing high-quality machined rings suitable for various applications such as jewelry-making or industrial components.

SYIL CNC Machine Features

When it comes to high-speed precision, the SYIL CNC machine is unmatched in its ability to produce intricate and accurate machined rings. With advanced technology and state-of-the-art equipment, the SYIL CNC machine ensures that each ring is crafted with the utmost precision, meeting the most demanding specifications.

High-Speed Precision

The SYIL CNC machine boasts high-speed precision, allowing for intricate and detailed machining of rings with unparalleled accuracy. This ensures that each ring meets the exact specifications required for various applications, from aerospace components to medical equipment.

The SYIL CNC machine also offers customizable options, allowing users to tailor the machining process to their specific needs. This flexibility ensures that the rings can be manufactured to exact specifications, whether it's a unique design or a specific material requirement. With customizable options, users can achieve the perfect balance of speed and precision for their particular project, making it an ideal choice for a wide range of applications.

Customizable Options

With customizable options, the SYIL CNC machine can tailor its machining process to meet specific design requirements for machined rings. Whether it's a unique shape or a specialized finish, the machine can be programmed to deliver custom solutions for a wide range of applications. This flexibility allows for greater creativity and innovation in product design, giving manufacturers the ability to bring their unique visions to life. By offering customizable options, the SYIL CNC machine ensures that each machined ring meets the exact specifications and standards set by the customer, resulting in high-quality, precision-engineered products.

Reliable Performance

The reliability of the SYIL CNC machine is second to none, providing consistent and dependable performance in producing machined rings. This reliability ensures that each ring meets stringent quality standards and delivers exceptional results every time.

By leveraging the high-speed precision, customizable options, and reliable performance of the SYIL CNC machine, businesses can achieve exceptional results in producing top-quality machined rings for various industries.

Applications of Machined Rings

Aerospace Industry

Machined rings are essential components in the aerospace industry, where precision and durability are paramount. These rings are used in aircraft engines, fuel systems, and hydraulic systems to ensure smooth and reliable operation. CNC machining allows for high precision ring machining, ensuring that the rings meet the stringent requirements of aerospace applications.

Medical Equipment

In the medical field, machined rings are used in a wide range of equipment such as surgical instruments, diagnostic devices, and implants. The high precision achieved through CNC machining ensures that these rings meet the strict quality standards required for medical applications. Whether it's for MRI machines or prosthetic devices, machined rings play a critical role in ensuring the reliability and performance of medical equipment.

Automotive Components

The automotive industry relies on machined rings for various components such as transmission systems, steering mechanisms, and engine parts. These rings need to withstand high levels of stress and heat while maintaining precise dimensions to ensure smooth operation. With CNC machining capabilities, manufacturers can produce high-quality machined rings from materials like stainless steel or tungsten that meet the rigorous demands of automotive applications.

Advantages of SYIL CNC Machining

When it comes to crafting high precision machined rings, SYIL CNC machining offers several advantages. The cost-efficiency of using a CNC machine for ring production is unmatched, as it allows for minimal material waste and reduced labor costs. Additionally, the time-saving nature of CNC machining ensures quick turnaround times for large-scale ring production, making it an ideal choice for businesses looking to meet tight deadlines. Furthermore, the consistent quality achieved through CNC machining guarantees that each machined ring meets exact specifications, ensuring uniformity across all products.

Cost-Efficiency

SYIL CNC machining offers unparalleled cost-efficiency when it comes to producing machined rings. By utilizing advanced technology and automation, CNC machines minimize material waste and optimize cutting processes, ultimately reducing overall production costs. This makes it an attractive option for businesses looking to maximize their budget while still delivering high-quality machined rings.

Time-Saving

In the realm of high precision ring machining, time is of the essence. With SYIL CNC machines, manufacturers can significantly reduce production lead times by streamlining the machining process and eliminating manual labor-intensive tasks. This not only allows for quicker order fulfillment but also enables businesses to stay competitive in fast-paced industries where efficiency is key.

In addition to saving time, SYIL CNC machines also ensure consistent quality in high precision ring machining. By automating the machining process, these machines can produce parts with a level of accuracy and precision that is difficult to achieve through manual labor. This means manufacturers can deliver products that meet the highest standards, leading to increased customer satisfaction and loyalty. Consistent quality is essential for building a strong reputation in the industry and attracting new business opportunities.

Consistent Quality

One of the standout advantages of SYIL CNC machining is its ability to consistently produce high-quality machined rings with precision and accuracy. The automated nature of CNC machines ensures that each ring is manufactured to exact specifications every time, resulting in uniformity across all products. This level of consistency is crucial for industries where reliability and performance are paramount.

Furthermore, the consistent quality of SYIL CNC machining also leads to cost savings for businesses. With each ring being produced to the same high standard, there is less need for rework or corrections, reducing the overall production time and costs. This reliability in quality also minimizes the risk of defects or malfunctions, ultimately saving money in the long run for companies in various industries.

Conclusion

When it comes to investing in quality machined rings, precision and durability are crucial. With SYIL CNC machines, you can trust in the reliability and high-performance capabilities for crafting high precision rings. Whether it's for the aerospace industry, medical equipment, or automotive components, machined rings play a vital role in enhancing product performance.

Investing in Quality Machined Rings

Investing in quality machined rings is essential for ensuring the longevity and performance of your products. With the use of high precision CNC machining, you can guarantee that each ring is crafted with the utmost accuracy and attention to detail. This ensures that your products will meet the highest standards of quality.

SYIL CNC Machine: A Reliable Choice

SYIL CNC machines are a reliable choice for producing machined rings with exceptional precision and efficiency. The customizable options and reliable performance make them an ideal choice for manufacturers looking to create top-quality products without compromising on accuracy or speed.

Enhancing Product Performance with Machined Rings

Machined rings play a crucial role in enhancing product performance across various industries such as aerospace, medical equipment, and automotive components. The use of high-quality materials and precision machining techniques ensures that these rings contribute to the overall reliability and functionality of the end products.