Introduction

In the world of precision machining, 5-axis milling has revolutionized the way complex parts are manufactured. With the ability to move a part or tool on five different axes simultaneously, a 5-axis CNC mill offers unparalleled versatility and efficiency. Whether you're a seasoned professional or just starting out, understanding the ins and outs of 5-axis milling is crucial for success in today's competitive manufacturing landscape.

Understanding 5-Axis Milling

The concept of 5-axis milling involves cutting away material from a workpiece on five different axes simultaneously. This allows for intricate and precise cuts that would be impossible with traditional 3-axis or even 4-axis machines. The ability to approach a workpiece from multiple angles enables manufacturers to easily create complex geometries, making it an essential tool for industries such as aerospace, automotive, and medical technology.

Benefits of 5 Axis CNC Milling

Five-axis CNC mills offer advantages over traditional machines, making them a valuable tool for manufacturers. Here's why:

- Machining Complex Parts: 5-axis mills excel at producing intricate geometries with tight tolerances. Moving and rotating the tool along five axes allows for machining complex angles and shapes that would be impossible with 3-axis machines.

- Reduced Setup Times: Complex parts often require multiple setups on a 3-axis machine. With 5-axis machining, many features can be completed in a single setup, significantly reducing overall production time.

- Increased Efficiency: Combining complex part machining with fewer setups increases efficiency. Manufacturers can produce parts faster and with less downtime.

- Space-Saving Desktop Options: Desktop 5-axis CNC mills offer the same benefits as their larger counterparts but with a smaller footprint. This makes them ideal for shops with limited floor space.

5-axis CNC mills allow manufacturers to produce complex parts efficiently, even in space-constrained environments.

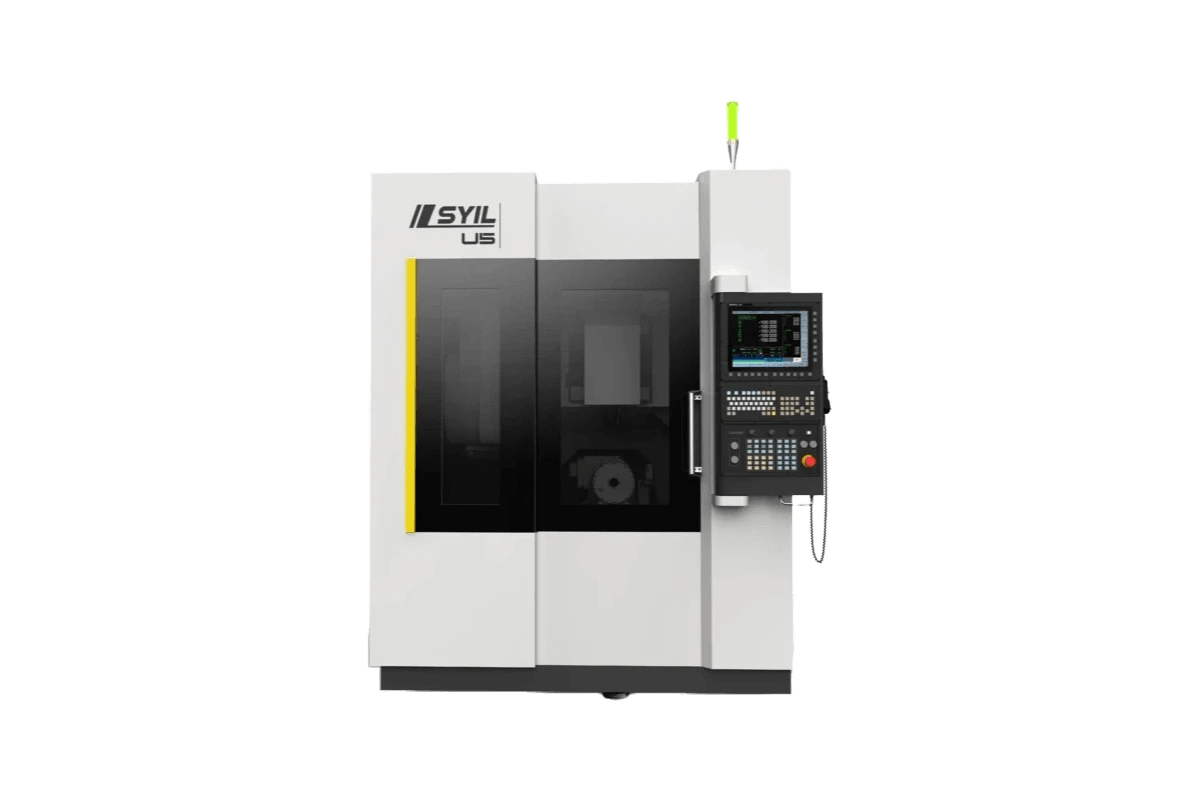

SYIL CNC Machine Overview

SYIL is at the forefront of desktop 5-axis CNC milling technology, offering cutting-edge machines perfect for hobbyists and professionals. Their range of compact yet powerful machines provides unparalleled precision and reliability, making them ideal for anyone looking to elevate their machining game. With SYIL's innovative features and user-friendly interface, achieving high accuracy in 5-axis milling has never been easier.

Importance of Precision in 5 Axis Milling

Precision is crucial in 5-axis milling as it allows for producing intricate and complex parts with tight tolerances. Achieving tight tolerances ensures that the final product meets exact specifications and requirements, which are essential in the aerospace, automotive, and medical technology industries.

Achieving Tight Tolerances

5-axis milling offers a decisive advantage for achieving tight tolerances in parts. Here's why:

- Precise Control: Unlike 3-axis machines, 5-axis milling allows for simultaneously machining complex geometries from multiple directions. This minimizes tool deflection and reduces the need for various setups, improving dimensional accuracy.

- Advanced Techniques: 5-axis milling facilitates advanced machining techniques like barrel finishing and ball nose machining, which can create smoother surface finishes and tighter tolerances compared to traditional methods.

- High-Quality Machines: Achieving tight tolerances relies heavily on the machine's capabilities. 5-axis CNC machines are designed with exceptional accuracy and repeatability, ensuring consistent results throughout the machining process.

The combination of precise control, advanced techniques, and high-quality machines makes 5-axis milling a superior choice for machining parts with demanding dimensional requirements.

Tools for Precision Machining

The quality of cutting tools is paramount in precision machining. High-performance end mills, drills, and other cutting tools are essential for achieving precise cuts and smooth finishes. Using the right tools for the job can significantly impact the overall precision of the machining process.

SYIL CNC Machine Capabilities

SYIL's desktop 5-axis CNC mill is a game-changer for machinists seeking unparalleled precision. Here's what sets it apart:

- Exceptional Rigidity and Stability: Advanced construction techniques deliver a rock-solid machine base, minimizing deflection and ensuring consistent toolpath accuracy.

- Effortless Tight Tolerance Machining: High-quality construction combined with advanced machining techniques allows users to achieve precision results that meet even the most demanding specifications.

- Simplified Efficiency: SYIL's 5-axis CNC mill streamlines the process of achieving tight tolerances. Simplifying the workflow and ensuring machine stability empowers machinists to produce high-quality parts efficiently.

SYIL's desktop 5-axis CNC mill empowers machinists with the tools and stability needed to achieve unparalleled precision and efficiency in their work.

Advanced Techniques for Precision Machining

Regarding precision machining, multi-axis strategies are crucial in achieving intricate and complex designs. A 5-axis mill allows for simultaneous movement of the cutting tool in multiple directions, resulting in more efficient and accurate machining processes. With the ability to approach the workpiece from any angle, SYIL's desktop 5-axis CNC mill offers unparalleled versatility and precision for a wide range of applications.

Multi-Axis Machining Strategies

SYIL's 5-axis CNC mill desktop is equipped with advanced multi-axis machining capabilities that enable intricate and precise cutting operations. The machine's simultaneous movement in multiple axes allows for complex geometries to be machined with ease, making it the best desktop 5-axis CNC mill for achieving high precision in manufacturing components for various industries.

High-Speed Machining

In addition to multi-axis capabilities, high-speed machining is another advanced technique contributing to precision machining. SYIL's 5-axis CNC mill is designed to deliver high-speed cutting without compromising accuracy, resulting in faster production cycles and superior surface finishes. This makes it the best desktop 5-axis CNC mill for maximizing productivity while maintaining exceptional precision.

SYIL CNC Machine Innovations

SYIL's innovative approach to CNC machine design incorporates cutting-edge technologies that enhance precision machining processes. From robust construction and high-performance spindles to advanced control systems, SYIL's 5-axis CNC mill desktop is engineered to deliver unmatched precision and reliability. With user-friendly features and state-of-the-art innovations, SYIL offers the best desktop 5-axis CNC mill for elevating your machining game.

By incorporating multi-axis machining strategies, high-speed cutting techniques, and innovative technologies into its design, SYIL's desktop 5-axis CNC mill sets a new standard for precision machining in various industries. Whether it's aerospace and defense, automotive, or medical technology applications, SYIL's 5-axis CNC mill delivers unparalleled accuracy and performance, elevating manufacturing processes to new heights.

Factors Affecting Precision in 5-Axis Milling

Material selection plays a crucial role in achieving precision in 5-axis milling. The choice of material can impact the machining process, affecting factors such as tool wear and surface finish. With the correct material selection, SYIL's CNC machine can easily handle a wide range of materials, ensuring high precision in every project.

Cutting tool quality is another key factor directly influencing precision in 5-axis milling. High-quality cutting tools are essential for maintaining tight tolerances and achieving superior surface finishes. SYIL's CNC machine is equipped with top-notch cutting tools designed to deliver exceptional performance and durability, ensuring precise results every time.

The durability of the CNC machine itself is also a significant factor in achieving precision in 5-axis milling. A robust and reliable machine like SYIL's desktop 5-axis CNC mill is essential for maintaining stability during the machining process, ultimately leading to consistent and accurate results.

By carefully considering these factors and leveraging the capabilities of SYIL's advanced desktop 5-axis CNC mill, manufacturers can elevate their machining game and achieve unparalleled precision in their projects.

Tips for Enhancing Precision in 5-Axis Milling

Proper workholding techniques in 5-axis milling require using the right fixtures and clamps to secure the workpiece in place. SYIL's desktop 5-axis CNC mill offers a range of work-holding options, including vises and modular fixturing systems, to ensure stability and accuracy during machining.

Proper Workholding Techniques

Proper work-holding techniques are essential for achieving precision in 5-axis milling. SYIL's best desktop 5-axis CNC mill provides a variety of work-holding solutions, such as vacuum tables and pallet changers, to accommodate different part sizes and shapes. Machinists can minimize vibration and maximize rigidity by utilizing these options, resulting in superior surface finishes and dimensional accuracy.

When it comes to software optimization for 5-axis CNC milling, choosing the right CAM software is key to maximizing efficiency and precision. SYIL's 5-axis CNC mill desktop is compatible with leading CAM packages, allowing users to generate toolpaths with advanced strategies like adaptive clearing and trochoidal milling for optimized cutting performance.

Software Optimization

SYIL's desktop 5-axis CNC mill is designed to integrate seamlessly with industry-leading CAM software, enabling users to fully take advantage of advanced toolpath generation capabilities. With efficient programming and simulation tools, machinists can optimize their cutting strategies for improved surface finish quality and reduced cycle times.

A 5-axis CNC mill's performance is critical in achieving precision machining results. SYIL's 5-axis CNC mill has high-quality components and robust construction to deliver exceptional rigidity and stability during cutting operations. This ensures consistent accuracy and repeatability across complex multi-sided parts.

SYIL CNC Machine Performance

SYIL's desktop 5-axis CNC mill offers outstanding performance capabilities that cater to the demands of high-precision machining applications. With features such as high-speed spindle options and intelligent motion control systems, this machine empowers users to tackle challenging projects confidently while maintaining superior accuracy levels.

By implementing proper work-holding techniques, leveraging software optimization tools, and harnessing the exceptional performance of SYIL's desktop 5-axis CNC mill, machinists can elevate their precision machining game to new heights while meeting the demands of diverse industry applications.

Industry Applications of High Precision 5-Axis Milling

Aerospace and Defense

Precision is paramount in the aerospace and defense industries, where safety and reliability are non-negotiable. Five-axis milling allows for intricate part designs with tight tolerances, making it ideal for components like turbine blades, missile parts, and aircraft structures. SYIL's desktop 5-axis CNC mill offers the precision needed for these critical applications.

The aerospace and defense industries require precision, efficiency, and cost-effectiveness in their manufacturing processes. 5-axis milling not only provides the necessary precision for critical components but also allows for faster production times and reduced labor costs. This makes SYIL's desktop 5-axis CNC mill a valuable asset for companies looking to streamline their production while maintaining the highest quality standards.

Automotive

In the automotive industry, 5-axis CNC milling is used to create complex parts such as engine components, transmission parts, and suspension systems. The ability to produce these parts with high precision ensures optimal vehicle performance and safety. SYIL's best desktop 5-axis CNC mill provides the accuracy required for automotive manufacturing processes.

In addition to creating engine components, transmission parts, and suspension systems, 5-axis CNC milling is also utilized in the automotive industry to produce intricate and lightweight body panels. These panels are essential for enhancing fuel efficiency and overall vehicle performance. With SYIL's best desktop 5-axis CNC mill, automotive manufacturers can quickly achieve the level of precision required to fabricate these complex body panels.

Medical Technology

The medical technology sector relies on high-precision machining for the production of surgical instruments, implants, and prosthetics. 5-axis milling enables intricate designs essential for medical devices to function effectively within the human body. SYIL's 5-axis CNC mill desktop offers the precision necessary for these life-saving applications.

In addition to precision, SYIL's 5-axis CNC mill desktop also offers efficiency and versatility. This means that medical technology companies can streamline their production processes and create a wider range of intricately designed medical devices. The ability to produce complex components with minimal setup time and fewer operations ultimately leads to cost savings for manufacturers in the medical technology sector.

Master Precision in 5-Axis Milling

When it comes to mastering precision in 5-axis milling, the key lies in understanding the importance of tight tolerances and advanced machining techniques. Choosing the right CNC machine is crucial, and when it comes to the best desktop 5-axis CNC mill, SYIL's CNC machine stands out for its capabilities and innovations. Elevate your machining game with SYIL's desktop 5-axis CNC mill and experience unparalleled precision and performance.

Mastering precision in 5-axis milling requires a deep understanding of achieving tight tolerances and utilizing advanced machining techniques. It's not just about cutting metal; it's about attaining perfection with every cut, and that's where SYIL's CNC machine excels. With its state-of-the-art technology and high-performance capabilities, SYIL's CNC machine allows intricate and complex designs to be executed with utmost precision, setting a new standard in the industry. Furthermore, the machine's user-friendly interface makes it accessible to operators of all skill levels, ensuring that the highest level of accuracy can be achieved consistently.

Choosing the Right CNC Machine

Choosing the right CNC machine is crucial for achieving precision in 5-axis milling. When it comes to the best desktop 5-axis CNC mill, SYIL's machine offers unparalleled capabilities, durability, and innovation that set it apart from the rest.

When it comes to choosing the right CNC machine for 5-axis milling, precision is key. SYIL's desktop 5-axis CNC mill stands out from the competition with its unparalleled capabilities, durability, and innovative features. With advanced technology and solid construction, this machine delivers the precision and performance needed for complex machining tasks. Whether you're working on prototypes or production parts, SYIL's CNC machine is designed to elevate your machining game and deliver exceptional results.

Elevating Your Machining Game with SYIL CNC Machine

Elevate your machining game with SYIL's desktop 5-axis CNC mill. With its advanced capabilities, high precision, and cutting-edge technology, SYIL's machine is designed to elevate your machining to new heights of excellence.

SYIL's desktop 5-axis CNC mill has advanced capabilities and cutting-edge technology. Still, it also offers user-friendly features that make it easy to operate for both experienced machinists and beginners. This means you can elevate your machining game without spending countless hours learning how to use the machine. Additionally, SYIL's machine is designed with high precision, ensuring that every cut and piece meets the highest quality standards.

Remember: When it comes to precision in 5-axis milling, choose a trusted partner like SYIL for unmatched performance and reliability.