Introduction

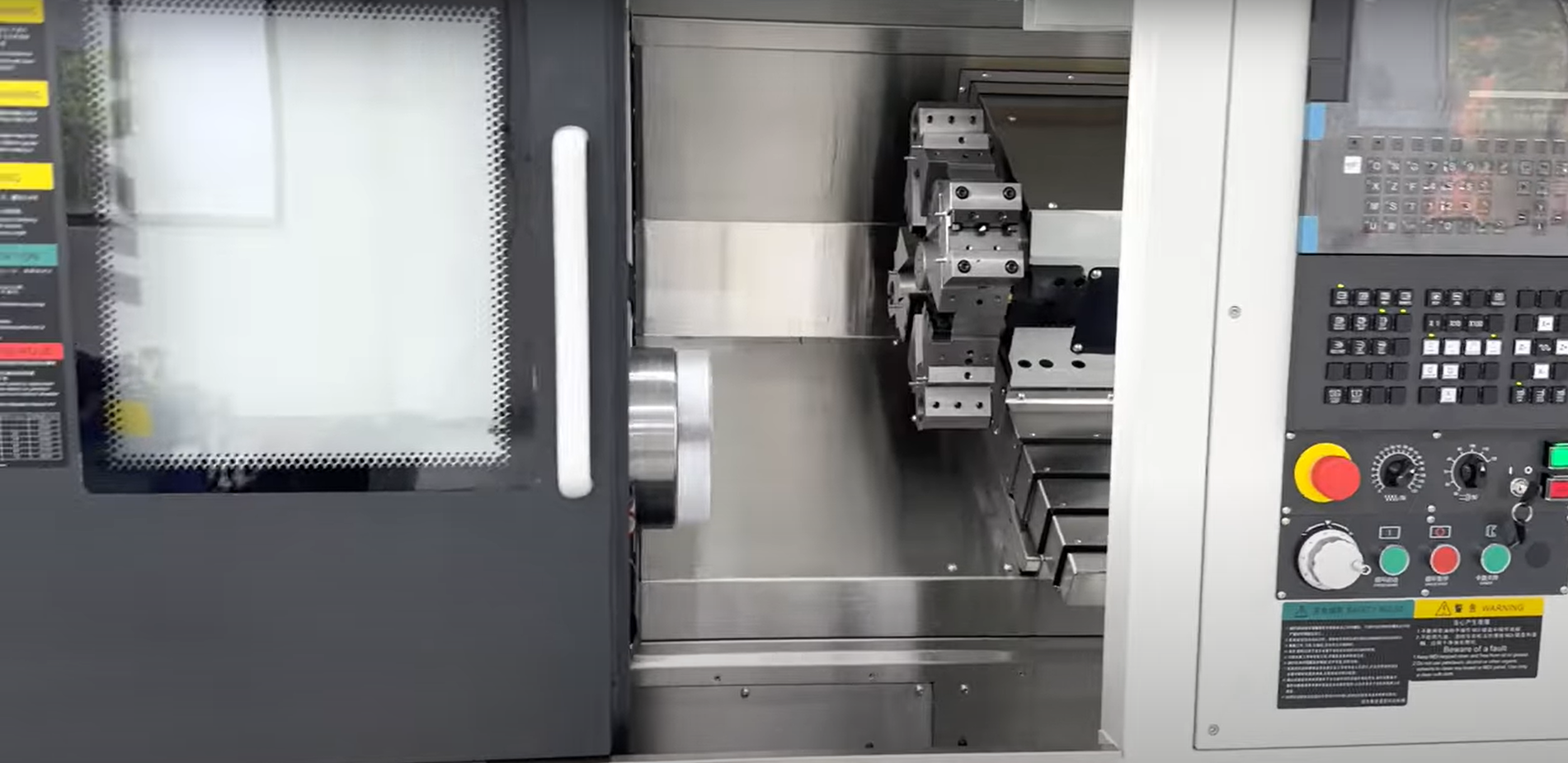

5-axis CNC machine manufacturers play a crucial role in producing high-quality precision parts. These advanced machines are at the forefront of CNC manufacturing, offering unparalleled capabilities in terms of complexity and accuracy. As an essential tool in modern production, CNC milling machines have revolutionized the way we approach manufacturing processes, allowing for increased efficiency and versatility.

What Are 5 Axis CNC Machine Manufacturers?

When it comes to 5-axis CNC machine manufacturers, SYIL CNC Machines stands out as a leader in the industry. With a strong focus on innovation and cutting-edge technology, SYIL has consistently delivered top-notch 5-axis CNC machines that meet the demands of modern manufacturing. Their commitment to quality and precision has made them a trusted name in the industry.

The Importance of CNC Milling Machines

Five-axis CNC milling machines have revolutionized manufacturing by offering unparalleled precision and versatility. Here's why they stand out:

- Unmatched Precision: By incorporating a fifth axis of movement, these machines can reach and machine complex features from various angles, resulting in parts with tighter tolerances and smoother finishes.

- Increased Versatility: Unlike traditional 3-axis machines, 5-axis systems can handle intricate designs in a single setup. This eliminates the need for multiple setups or manual manipulation, streamlining production and reducing errors.

- Improved Productivity: Automation and efficient multi-axis machining significantly accelerate production compared to manual processes. This translates to faster turnaround times and higher output.

Overall, 5-axis CNC milling machines empower manufacturers to achieve superior quality, tackle complex designs, and boost productivity, making them a cornerstone of modern manufacturing operations.

Understanding

5-Axis Machining Precision

The concept of 5-axis machining precision revolves around the machine's ability to move along five different axes simultaneously, allowing complex geometries to be machined with exceptional accuracy. This level of precision is crucial in industries such as aerospace, automotive, and medical sectors, where intricate components are required.

The ability of 5-axis machining precision to create intricate components with exceptional accuracy has revolutionized manufacturing in the aerospace, automotive, and medical industries. This level of precision allows for producing complex geometries that were previously impossible to achieve with traditional machining methods. As a result, manufacturers can now produce parts and components with tighter tolerances and higher quality, improving the final product's performance and reliability.

Top 5 Axis CNC Machine Manufacturers

When it comes to 5-axis CNC machine manufacturers, several industry leaders stand out for their innovation and excellence in CNC manufacturing. These companies have consistently delivered top-notch CNC milling machines with precision and reliability, making them the go-to choice for businesses looking to invest in 5-axis machining technology.

SYIL CNC Machines: A Leader in 5 Axis CNC Manufacturing

SYIL CNC Machines has established itself as a leader in 5-axis CNC manufacturing, offering a wide range of high-quality machines designed to meet the needs of various industries. With a strong focus on innovation and customer satisfaction, SYIL's CNC machines are known for their superior precision and advanced technology, making them popular among businesses seeking reliable and efficient 5-axis CNC solutions.

Haas Automation: Innovating CNC Machine Milling

Haas Automation is renowned for its cutting-edge approach to CNC machine milling, consistently pushing the industry's innovation boundaries. Their commitment to advancing 5-axis machining technology has earned them a stellar reputation among manufacturers seeking state-of-the-art solutions for their production needs.

Mazak Corporation: Excellence in

5-Axis Machining

Mazak Corporation has long been synonymous with excellence in 5-axis machining. It delivers high-performance CNC milling machines that offer unparalleled precision and versatility. Its dedication to quality and innovation has made it a trusted name in the world of manufacturing.

Okuma Corporation: Pioneering

5-Axis CNC Technology

Okuma Corporation has been at the forefront of pioneering 5-axis CNC technology, consistently introducing groundbreaking advancements that have revolutionized the industry. With a strong focus on technological innovation and engineering excellence, Okuma's machines are widely recognized for their reliability and cutting-edge capabilities.

DMG Mori: Advancements in

5-Axis CNC Machines

DMG Mori is known for its relentless pursuit of advancements in 5-axis CNC machines. It constantly pushes the envelope with state-of-the-art solutions that cater to diverse manufacturing needs. Its commitment to continuous improvement and customer satisfaction has positioned it as a leading provider of innovative machining technologies.

As you can see from our list above, each of these top manufacturers brings something unique to the table when it comes to 5-axis CNC machine manufacturing—whether it's SYIL's commitment to customer satisfaction or Haas Automation's innovative approach towards CNC machine milling—making them all worthy contenders for businesses looking to invest in top-quality machinery.

Stay tuned for our next section, where we'll discuss factors to consider when choosing a manufacturer!

Factors to Consider When Choosing a 5 Axis CNC Machine Manufacturer

When selecting a 5-axis CNC machine manufacturer, it's crucial to consider the level of technology and innovation they bring to the table. Look for companies that are at the forefront of 5-axis CNC technology, offering cutting-edge solutions for precision machining and efficient production processes.

Technology and Innovation in 5 Axis CNC

SYIL CNC Machines is a leader in technology and innovation in 5-axis CNC machines. With their state-of-the-art designs and advanced software integration, SYIL is revolutionizing the manufacturing industry by providing high-tech solutions for complex machining needs.

Quality and Precision in CNC Machining

In addition to technological advancements, it's essential to prioritize quality and precision when choosing a 5-axis CNC machine manufacturer. SYIL's commitment to superior craftsmanship and attention to detail ensures that its machines deliver impeccable results with every use, setting it apart from other manufacturers in the market.

Customer Support and Service in CNC Manufacturing

Reliable customer support and service are paramount when investing in a 5-axis CNC machine. SYIL not only offers top-notch machines but also exceptional customer support, ensuring that clients can access technical assistance, training, and maintenance services whenever needed.

By prioritizing technology innovation, quality precision machining, and exceptional customer support, SYIL emerges as the premier choice for those seeking a reliable 5-axis CNC machine manufacturer.

Advantages of Using 5 Axis CNC Machines

Increased Efficiency and Productivity in CNC Machining

5-axis CNC machines offer a game-changing advantage for manufacturers: increased efficiency and productivity. Here's how they achieve this:

- Single-Setup Machining: 5-axis machines can access multiple sides of a workpiece simultaneously, eliminating the need for various setups and reducing overall production time.

- Reduced Labor Costs: Fewer setups translate to less manual intervention, lowering labor costs and streamlining manufacturing processes.

- Faster Completion Times: The ability to machine complex parts in one go significantly reduces production time, allowing manufacturers to meet tight deadlines more efficiently.

- Increased Project Capacity: With faster turnaround times, manufacturers can take on more projects and expand their production capabilities.

5-axis CNC machines revolutionize production efficiency by enabling single-setup machining, reducing labor costs, and accelerating project completion times. This allows manufacturers to thrive in a competitive market.

Versatility and Flexibility in 5 Axis CNC

5-axis CNC machines provide unparalleled versatility and flexibility, allowing for a broader range of machining capabilities than traditional 3-axis machines. Accessing multiple sides of a workpiece without repositioning enables intricate and precise cutting, resulting in smoother surface finishes and more intricate designs. These machines can handle various manufacturing needs, whether it's aerospace components, automotive parts, or medical devices.

Superior Precision and Accuracy in

5-Axis Machining

Precision is paramount in manufacturing, and 5-axis CNC machines deliver superior accuracy. Their advanced design enables them to achieve complex geometries with tight tolerances, ensuring consistent quality across all machined parts. This level of precision enhances product performance and reduces material waste, making them an ideal choice for high-precision industries like aerospace and medical.

With SYIL's innovative approach to 5-axis CNC manufacturing, our machines have cutting-edge technology that maximizes efficiency while maintaining exceptional precision. From small-scale workshops to large-scale production facilities, our versatile range of 5-axis CNC machines offers unmatched flexibility for various manufacturing needs.

The advantages of 5-axis CNC machines make them indispensable for manufacturers seeking to elevate their production capabilities. With SYIL's commitment to innovation and quality craftsmanship, our advanced machinery is poised to revolutionize how industries approach machining processes.

Common Applications of 5-Axis CNC Machines

The aerospace industry heavily relies on 5-axis CNC machines to produce complex and precise parts for aircraft and spacecraft. From turbine blades to fuselage components, the versatility and accuracy of 5-axis machining play a crucial role in meeting the sector's stringent requirements.

Aerospace Industry Utilization of 5 Axis CNC

In the automotive industry, 5-axis machining has become indispensable for creating intricate components such as engine blocks, transmission parts, and chassis elements. The ability to efficiently produce complex shapes with tight tolerances makes 5-axis CNC machines a valuable asset in streamlining manufacturing processes and enhancing overall productivity.

In the aerospace industry, 5-axis CNC machines have also revolutionized the manufacturing process by enabling the production of complex components such as turbine blades, aircraft wings, and structural elements with unparalleled precision. This technology allows aerospace manufacturers to achieve intricate designs and geometries that were previously unattainable, leading to lighter and more efficient aircraft structures. The integration of 5-axis machining in the aerospace sector has improved the overall quality of components and contributed to reducing material waste and production costs.

Automotive Industry Integration of

5-Axis Machining

The medical and dental sectors have embraced CNC milling technology for fabricating custom implants, prosthetics, and orthodontic devices. The precision and repeatability offered by 5-axis CNC machines enable manufacturers to meet the unique demands of patient-specific medical devices with utmost accuracy and efficiency.

Medical and Dental Sector Adoption of CNC Milling

The medical and dental sector has increasingly embraced using CNC milling to produce custom implants, prosthetics, and other medical devices. With the precision and accuracy offered by 5-axis CNC machines, manufacturers can create intricate and customized components that perfectly fit each patient's unique needs. This technology has revolutionized how medical and dental professionals approach patient care, allowing faster production times and improved patient outcomes. As a result, the adoption of CNC milling in the medical and dental industry continues to grow as manufacturers recognize its significant benefits in terms of customization and quality.

The Future of 5-Axis CNC Machine Manufacturers

Advancements in

5-Axis CNC Technology

As technology continues to evolve, 5 axis CNC machine manufacturers are constantly making advancements to enhance their machines' capabilities. From improved spindle speeds to more efficient tool changers, these technological developments are geared toward increasing productivity and precision in CNC machining.

Integration of Artificial Intelligence in CNC Machining

AI is transforming CNC machining by bringing intelligence and automation to the forefront. Here's how:

- Optimized Tool Paths: AI algorithms analyze data to generate the most efficient tool paths, minimizing travel time and maximizing material usage.

- Predictive Maintenance: By analyzing sensor data, AI can predict potential machine failures before they occur, preventing costly downtime and ensuring smooth operations.

- Self-Adjusting Parameters: AI can analyze real-time data and adjust cutting parameters like speed and feed rate for optimal performance, ensuring consistent product quality.

These AI-powered capabilities revolutionize CNC machining, enabling manufacturers to tackle complex tasks with greater efficiency, accuracy, and reduced costs. As AI continues to evolve, the future of CNC machining promises even greater automation and optimization.

Sustainable Manufacturing Practices in

5-Axis CNC

In today's environmentally conscious world, sustainability is a key focus for 5-axis CNC machine manufacturers. These companies are committed to reducing their environmental impact while maintaining high-quality production standards by implementing energy-efficient components, recyclable materials, and waste-reducing processes.

SYIL’s commitment to innovation and sustainability sets it apart as a leader among 5-axis CNC machine manufacturers. Focusing on cutting-edge technology and eco-friendly manufacturing practices, SYIL’s machines offer top-notch precision and efficiency while minimizing environmental impact. As the future unfolds, SYIL remains at the forefront of shaping the next generation of 5-axis CNC machining.

By embracing these future trends in technology, artificial intelligence integration, and sustainable practices, 5-axis CNC machine manufacturers are poised to continue revolutionizing the manufacturing industry with their innovative solutions. As demand for high-precision components grows across various sectors, these advancements will play a crucial role in meeting the evolving needs of modern manufacturing processes.

Choose the Right 5 Axis CNC Machine Manufacturer

When selecting a 5-axis CNC machine manufacturer, it's crucial to consider factors such as technological advancements, precision, and customer support. SYIL CNC Machines stands out as a leader in the industry, offering innovative solutions and exceptional quality in CNC manufacturing. In addition to these essential factors, SYIL prioritizes affordability without compromising on the performance of their machines. This makes them an attractive option for businesses investing in cutting-edge technology without breaking the bank. Furthermore, SYIL's commitment to continuous improvement means that customers can trust they will get state-of-the-art equipment to meet their evolving needs.

Embracing the Future of CNC Machining

As technology continues to evolve, embracing the future of CNC machining is essential for staying competitive. Integrating artificial intelligence and sustainable manufacturing practices will shape the industry's future, offering new possibilities for efficiency and innovation.

5 Axis CNC Machines: Revolutionizing Manufacturing

The introduction of 5-axis CNC machines has revolutionized manufacturing processes across various industries. With increased efficiency, versatility, and superior precision, these machines have become indispensable tools for achieving high-quality results in machining operations.