Introduction

When it comes to aluminum fabrication, CNC machines play a crucial role in achieving precision and efficiency. Understanding the basics of CNC for aluminum is essential for maximizing the potential of these machines. That's where SYIL CNC Machines come into play, unlocking the secrets to efficient aluminum machining.

The Basics of CNC for Aluminum

CNC stands for Computer Numerical Control, which involves using computer software to control machine tools in order to automate and optimize the manufacturing process. When it comes to aluminum, CNC machines offer numerous advantages. Aluminum is a lightweight and versatile metal that requires careful machining techniques to achieve accurate results.

Why CNC Machines are Essential for Aluminum Fabrication

CNC machines are revolutionizing aluminum fabrication by offering several key advantages. Here's why they are essential for modern manufacturers:

- Precision and Consistency: CNC machines guarantee precise and consistent results, unlike traditional manual machining methods that are prone to human error. This ensures that every aluminum part meets exact specifications.

- Increased Productivity: CNC machines automate the fabrication process, significantly boosting production rates compared to manual machining. This allows manufacturers to produce parts faster and meet higher demands.

- Enhanced Quality Control: CNC machines allow for stricter quality control by ensuring all parts meet the exact specifications programmed into the machine. This minimizes defects and ensures consistent quality throughout a production run.

CNC machines are a game-changer for aluminum fabrication. Their ability to deliver precise, consistent, and high-quality parts at an accelerated pace makes them an essential tool for modern manufacturers.

SYIL CNC Machines: Unlocking the Secrets to Efficient Aluminum Machining

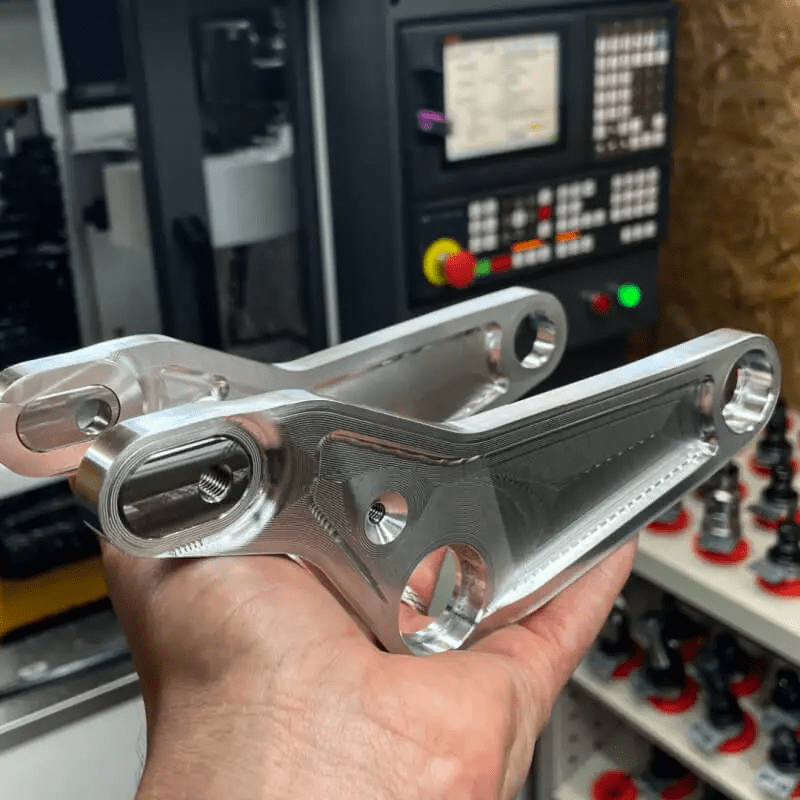

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's range of CNC machines specifically designed for aluminum fabrication offers cutting-edge technology and innovative features that enhance productivity, accuracy, and surface finish.

Choosing the Right CNC Machine for Aluminum Fabrication

When it comes to aluminum fabrication, selecting the right CNC machine is crucial for achieving optimal results. There are several factors to consider in order to make an informed decision.

Factors to Consider When Selecting a CNC Machine for Aluminum

- Machine Rigidity: Aluminum is a soft metal that requires a CNC machine with high rigidity to prevent vibrations and deflection during machining. Look for machines with robust frames and components that can withstand the demands of aluminum fabrication.

- Spindle Power and Speed: The spindle power and speed play a crucial role in aluminum machining. Higher spindle power allows for faster material removal rates, while adjustable speed settings ensure precise control over cutting operations.

- Tool Changer Capacity: Aluminum machining often involves using multiple tools for different operations. Therefore, it is essential to choose a CNC machine with an adequate tool changer capacity to minimize downtime and maximize efficiency.

- Worktable Size: Consider the size of your aluminum workpieces when selecting a CNC machine. Ensure that the worktable can accommodate your largest parts without compromising stability or maneuverability.

- Accuracy and Precision: Aluminum fabrication demands high accuracy and precision to achieve tight tolerances and smooth surface finishes. Look for CNC machines equipped with advanced control systems that offer precise positioning and excellent repeatability.

Exploring SYIL's Range of CNC Machines for Aluminum Fabrication

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling, including a range specifically designed for aluminum fabrication. Their machines excel in all the factors mentioned above, making them an ideal choice for aluminum machining projects.

SYIL's CNC machines feature robust frames made from high-quality materials, ensuring exceptional rigidity during aluminum fabrication processes. With powerful spindles capable of delivering high speeds, these machines enable efficient material removal rates while maintaining accuracy.

Equipped with automatic tool changers, SYIL CNC machines streamline the machining process by eliminating manual tool swaps and reducing downtime. This allows for uninterrupted production and increased productivity in aluminum fabrication.

The Advantages of Using SYIL CNC Machines for Aluminum

SYIL Machine Tools' CNC machines offer several advantages specifically tailored to aluminum fabrication:

- Precision and Accuracy: SYIL's advanced control systems enable precise positioning, ensuring accurate cuts and maintaining tight tolerances throughout the machining process.

- High Efficiency: With powerful spindles and adjustable speed settings, SYIL CNC machines optimize material removal rates, resulting in faster production times and increased efficiency.

- Reliability and Durability: SYIL's commitment to quality ensures that their CNC machines are built to last. The robust construction and high-quality components guarantee long-term reliability, minimizing downtime and maintenance costs.

By choosing a SYIL CNC machine for your aluminum fabrication needs, you can unlock the full potential of precision machining while enjoying the benefits of efficiency, reliability, and durability.

Optimizing CNC Machining Parameters for Aluminum

Understanding Aluminum Alloys and Their Machinability

When it comes to CNC machining for aluminum, understanding the different aluminum alloys and their machinability is crucial. Aluminum alloys vary in composition and properties, which can affect how they are machined. Some common aluminum alloys used in fabrication include 6061, 7075, and 2024. These alloys have different levels of hardness, strength, and thermal conductivity, which must be taken into account when optimizing machining parameters.

Fine-Tuning Speeds and Feeds for Aluminum CNC Machining

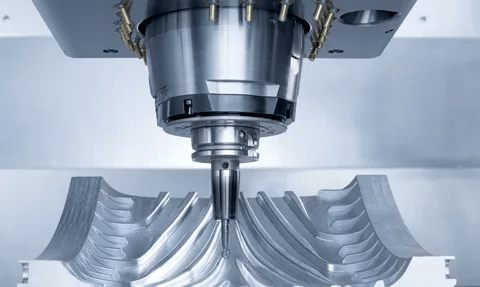

Fine-tuning speeds and feeds is essential to achieve optimal results in aluminum CNC machining. The cutting speed refers to the speed at which the tool moves across the surface of the material, while feed rate refers to how fast the tool advances into the material. For aluminum, higher cutting speeds and feed rates are generally preferred due to its lower melting point compared to other metals.

SYIL's CNC machines for aluminum offer advanced control systems that allow for precise adjustment of cutting speeds and feed rates. This ensures efficient material removal while minimizing tool wear and maintaining dimensional accuracy.

SYIL's Smart Control Systems for Precision Aluminum Machining

SYIL Machine Tools takes precision aluminum machining to another level with their smart control systems. These systems integrate advanced technology to monitor and optimize machining parameters in real-time. By constantly analyzing data such as cutting forces, temperatures, and vibrations, SYIL's control systems can make automatic adjustments during the machining process.

The smart control systems also provide operators with valuable insights into machine performance and tool life expectancy. With this information at their fingertips, operators can make informed decisions to maximize productivity while ensuring high-quality results.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By optimizing CNC machining parameters for aluminum, SYIL's CNC machines offer exceptional performance and reliability in aluminum fabrication. Empower your aluminum fabrication with SYIL's precision CNC solutions to unlock the full potential of CNC for aluminum.

Tooling and Tool Selection for CNC Aluminum Machining

In CNC aluminum machining, proper tooling is crucial for achieving accurate and efficient results. The right tools can significantly impact the quality of the final product and the overall machining process.

When it comes to aluminum machining, there are several essential tools that every CNC operator should have in their arsenal. These include end mills, drills, reamers, and taps specifically designed for aluminum. These tools are optimized to withstand the unique properties of aluminum, such as its low melting point and tendency to generate chips.

SYIL Machine Tools understands the importance of having high-quality tools for CNC aluminum machining. Their cutting-edge tooling solutions are specifically engineered to deliver exceptional performance and durability when working with aluminum. With SYIL's tools, operators can achieve precise cuts and minimize tool wear, resulting in superior finished products.

By offering a wide range of tooling options tailored for CNC aluminum machining, SYIL empowers operators to optimize their workflow and maximize productivity. Whether it's roughing or finishing operations, SYIL's tooling solutions ensure consistent performance and excellent surface finishes.

Overcoming Challenges in CNC Aluminum Machining

Aluminum machining presents unique challenges that require careful consideration and innovative solutions. Two key challenges in CNC aluminum machining are heat and chip control, as well as minimizing vibration and deflection. SYIL Machine Tools understands these challenges and offers cutting-edge solutions to tackle them effectively.

Dealing with Heat and Chip Control in Aluminum Machining

Heat control is crucial in aluminum machining to prevent thermal damage to the material and ensure optimal cutting conditions. Aluminum has a high thermal conductivity, which means it quickly absorbs and dissipates heat during the machining process. To deal with this challenge, SYIL's CNC machines for aluminum feature advanced cooling systems that efficiently remove heat from the cutting zone, ensuring precise and consistent performance.

Additionally, effective chip control is essential in aluminum machining to avoid chip recutting, which can lead to poor surface finishes and tool wear. SYIL's CNC machines for aluminum are equipped with specially designed chip evacuation systems that effectively remove chips from the cutting area, preventing them from interfering with the machining process.

Minimizing Vibration and Deflection in Aluminum CNC Machining

Vibration and deflection can significantly impact the accuracy and quality of aluminum machining. Aluminum is a relatively soft material compared to other metals, making it prone to vibration during cutting operations. Excessive vibration can result in poor surface finishes, dimensional inaccuracies, and reduced tool life.

SYIL's CNC machines for aluminum are engineered with robust structures that minimize vibration and deflection during machining operations. These machines utilize advanced damping technologies that absorb vibrations, ensuring stable cutting conditions for precise results.

SYIL's Innovative Solutions for Tackling Aluminum Machining Challenges

SYIL Machine Tools is committed to providing innovative solutions for overcoming challenges in CNC aluminum machining. Their precision CNC machines incorporate state-of-the-art technologies such as intelligent temperature control systems that monitor and regulate the temperature during the machining process, ensuring optimal conditions for aluminum machining.

Furthermore, SYIL offers a range of tooling solutions specifically designed for aluminum machining. These cutting-edge tools are optimized for efficient chip evacuation, heat dissipation, and superior surface finishes.

By investing in SYIL's CNC machines for aluminum, manufacturers can overcome the challenges associated with this versatile metal and unlock its full potential. With their precision and reliability, SYIL machines empower aluminum fabricators to achieve exceptional results while maximizing productivity and profitability.

Achieving the Best Surface Finish in CNC Aluminum Machining

Achieving a high-quality surface finish is crucial in CNC aluminum machining to ensure the desired aesthetics and functionality of the finished parts. Understanding the surface finish requirements for aluminum parts is the first step towards achieving exceptional results.

When it comes to aluminum parts, surface finish requirements can vary depending on the specific application. For example, aerospace components may require a smooth and reflective finish for improved aerodynamics, while automotive parts may need a textured or matte finish for better grip and durability.

To meet these requirements, various techniques can be employed in aluminum machining. One common technique is using high-speed machining strategies that reduce tool marks and improve surface smoothness. Additionally, employing proper coolant systems can help control heat generation during machining, resulting in better surface finishes.

SYIL Machine Tools offers advanced surface finish capabilities specifically designed for aluminum machining. Their CNC machines incorporate state-of-the-art technologies such as vibration damping systems and advanced spindle designs to minimize tool chatter and achieve superior finishes. With SYIL's precision CNC solutions, you can consistently achieve the best surface finishes for your aluminum parts.

In conclusion, achieving the best surface finish in CNC aluminum machining requires understanding the specific requirements of your parts and employing appropriate techniques. SYIL Machine Tools provides advanced solutions that enable you to achieve exceptional finishes consistently. With their precision CNC machines for milling and drilling, you can unlock the full potential of your aluminum fabrication projects while prioritizing quality and sustainability.

Remember, when it comes to CNC machines for metal fabrication, SYIL Machine Tools stands out as a reliable partner that prioritizes customer satisfaction through innovative solutions and cutting-edge technology.

Master CNC Aluminum Machining: Unleashing the Full Potential of SYIL CNC Machines

When it comes to CNC aluminum machining, SYIL Machine Tools stands out as a leader in the industry. With their precision CNC machines specifically designed for milling and drilling aluminum, they offer unrivaled quality and efficiency. By mastering the art of CNC aluminum machining, you can unlock the full potential of SYIL CNC machines and take your fabrication process to new heights.

Empowering Your Aluminum Fabrication with SYIL's Precision CNC Solutions

SYIL Machine Tools understands the unique challenges that come with aluminum fabrication. That's why they have developed precision CNC solutions tailored specifically for working with this versatile metal. By using their cutting-edge technology and advanced features, you can empower your aluminum fabrication process and achieve exceptional results.

Unlock the Secrets of CNC for Aluminum with SYIL Machine Tools

SYIL Machine Tools has spent years perfecting their CNC machines for aluminum, unlocking the secrets to efficient and precise machining. With their expertise and innovative solutions, they have revolutionized the way aluminum is machined. By choosing SYIL's state-of-the-art machines, you can unlock these secrets yourself and elevate your aluminum machining capabilities.