Introduction

In today's competitive manufacturing industry, choosing the right vertical CNC machining center is crucial for achieving precision and efficiency in your operations. With the wide range of options available, it can be overwhelming to find the perfect fit for your specific needs. That's where SYIL Machine Tools comes in as your trusted source for precision CNC machines.

The Importance of Choosing the Right Vertical CNC Machining Center

Investing in a high-quality vertical CNC machining center is essential for ensuring accurate and reliable results in your machining processes. Whether you're working on complex workpieces or simple components, having a machine that meets your requirements is vital to maintaining productivity and minimizing errors.

SYIL Machine Tools: Your Trusted Source for Precision CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their commitment to innovation and customer satisfaction has made them a trusted partner in the industry.

Advanced Technology and Features

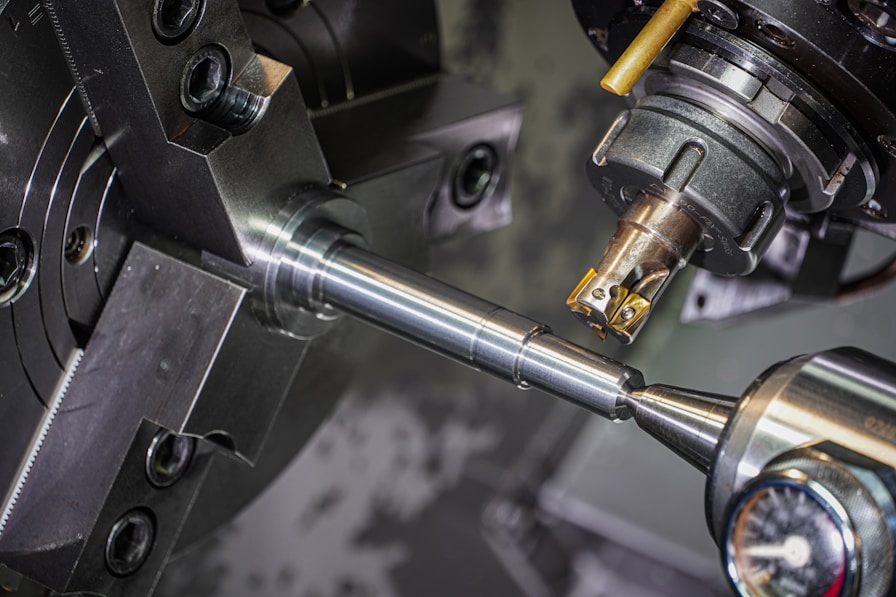

SYIL Machine Tools offers advanced technology and features in their vertical CNC machining centers, ensuring precision and efficiency in manufacturing processes.

High Precision and Accuracy: Achieving Exceptional Results

SYIL's vertical CNC machining centers are equipped with cutting-edge technology that enables high precision and accuracy in every machining operation. With state-of-the-art control systems and advanced motion control algorithms, these machines can achieve exceptional results with tight tolerances. Whether you need to mill, drill, or turn complex workpieces, SYIL's vertical CNC machining centers deliver the accuracy needed for your projects.

Integrated CAD/CAM Software: Streamlining Workflow Efficiency

To streamline workflow efficiency, SYIL's vertical CNC machining centers come with integrated CAD/CAM software. This powerful software allows operators to design and program their parts directly on the machine, eliminating the need for external programming tools. The seamless integration of CAD/CAM software not only saves time but also ensures accurate translation of design specifications into machine instructions. This feature enhances productivity by reducing manual errors and optimizing tool paths for efficient machining operations.

Automatic Tool Changer: Reducing Downtime and Increasing Productivity

SYIL's vertical CNC machining centers are equipped with an automatic tool changer that significantly reduces downtime and increases productivity. With a large tool capacity, operators can load multiple tools into the machine at once, allowing for uninterrupted machining operations without manual intervention. The automatic tool changer also enables quick tool changes during the production process, minimizing setup time between different operations. This feature maximizes efficiency by eliminating idle time spent on manual tool changes and improves overall productivity.

By incorporating high precision and accuracy, integrated CAD/CAM software, and an automatic tool changer into their vertical CNC machining centers, SYIL Machine Tools ensures that manufacturers can achieve exceptional results with streamlined workflow efficiency. With over 12k machines supplied globally, SYIL is a trusted partner for precision and efficiency in manufacturing.

Versatility and Flexibility

When it comes to versatility and flexibility, SYIL Machine Tools' vertical CNC machining centers are in a league of their own. These machines offer a range of capabilities that allow manufacturers to expand their machining options and tackle complex workpieces with ease.

Vertical Turning Center Capability: Expanding Machining Options

SYIL's vertical CNC machining centers come equipped with vertical turning center capability, which opens up a whole new world of possibilities for manufacturers. This feature allows for the turning of cylindrical workpieces on a vertical axis, offering greater precision and control. Whether you need to create intricate details or produce large-scale components, the vertical turning center capability gives you the flexibility to do it all.

Multi-Axis Machining: Tackling Complex Workpieces with Ease

Complex workpieces often require intricate cuts and precise angles. With SYIL's multi-axis machining feature, manufacturers can effortlessly tackle these challenging projects. The machines are equipped with multiple axes that provide enhanced maneuverability and allow for simultaneous movement in different directions. This capability ensures that even the most complex workpieces can be machined accurately and efficiently.

Flexible CNC Bed: Adapting to Various Production Needs

SYIL's vertical CNC machining centers feature a flexible CNC bed that can adapt to various production needs. This means that manufacturers can easily switch between different setups without the need for extensive reconfiguration or adjustments. Whether you're working on small-scale projects or large-scale production runs, the flexible CNC bed ensures optimal efficiency and adaptability.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their vertical CNC machining centers offer unparalleled versatility and flexibility, allowing manufacturers to expand their machining options and tackle complex workpieces with ease. Additionally, the flexible CNC bed ensures adaptability to various production needs. Invest in a SYIL vertical CNC machining center today and unlock your production potential.

Reliable Performance and Durability

When it comes to reliable performance and durability, SYIL Machine Tools' vertical CNC machining centers are second to none. With their integration of Doosan VMC technology, these machines offer proven quality and reliability. The Doosan VMC integration ensures that every component works seamlessly together, resulting in a machine that consistently delivers exceptional results.

In addition to the Doosan VMC integration, SYIL's vertical CNC machining centers also boast rigid construction. This provides stability and longevity, allowing the machines to withstand heavy-duty use without compromising precision. Whether you're working with large workpieces or tackling complex projects, you can trust that these machines will remain stable throughout the machining process.

Furthermore, SYIL Machine Tools uses only high-quality components in their vertical CNC machining centers. From the spindle to the control system, every part is carefully selected to ensure consistency and performance. This attention to detail guarantees that each machine operates at its best, delivering accurate and reliable results every time.

With SYIL's focus on reliability and durability, you can trust that their vertical CNC machining centers will meet your production needs and withstand the test of time. Whether you're a small shop or a large manufacturing facility, investing in one of these machines will ensure that you have a reliable workhorse for years to come.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their vertical CNC machining centers offer advanced technology features such as high precision and accuracy, integrated CAD/CAM software for streamlined workflow efficiency, automatic tool changers for reduced downtime, versatility with vertical turning center capability and multi-axis machining, flexibility with a CNC bed that adapts to various production needs, and cost-effective solutions with competitive pricing, reduced maintenance and operational costs, and energy-saving features. With excellent customer support and service, SYIL Machine Tools is the ultimate solution for precision and efficiency in manufacturing. Invest in a vertical CNC machining center from SYIL Machine Tools today and unlock your production potential.

Cost-Effective Solution

When it comes to investing in a vertical CNC machining center, cost-effectiveness is a crucial factor to consider. SYIL Machine Tools understands the importance of providing value for your investment and offers competitive pricing options. With SYIL's machines, you can get more bang for your buck without compromising on quality or performance.

SYIL's Flex CNC series, including the vertical turning center and CNC bed models, are designed to offer exceptional value at an affordable price point. These machines provide the precision and efficiency needed for various machining tasks while being budget-friendly.

Competitive Pricing: Getting More Value for Your Investment

SYIL Machine Tools aims to make precision CNC machines accessible to businesses of all sizes. With their competitive pricing strategy, they ensure that customers receive maximum value for their investment. Whether you're a small workshop or a large-scale manufacturing facility, SYIL's vertical CNC machining centers offer affordability without sacrificing quality.

By choosing SYIL as your trusted source for precision CNC machines, you can save significantly compared to other manufacturers in the market. This cost advantage allows you to allocate resources towards other aspects of your business while still benefiting from top-notch machining capabilities.

Reduced Maintenance and Operational Costs: Maximizing Efficiency

In addition to competitive pricing, SYIL's vertical CNC machining centers also help minimize maintenance and operational costs. These machines are built with durability in mind, ensuring long-term reliability and reducing the need for frequent repairs or replacements.

With SYIL's advanced technology and high-quality components, you can expect minimal downtime due to breakdowns or malfunctions. This translates into increased productivity and efficiency in your manufacturing processes.

Furthermore, SYIL Machine Tools provides excellent customer support and service, offering expert technical assistance when needed. Their team of professionals is readily available to address any concerns or troubleshoot issues promptly, minimizing costly disruptions in your operations.

Energy-Saving Features: Promoting Sustainability and Environmental Responsibility

SYIL Machine Tools understands the importance of sustainability and environmental responsibility in today's manufacturing landscape. That's why their vertical CNC machining centers are equipped with energy-saving features that promote efficient energy consumption.

By optimizing power usage, SYIL's machines help reduce energy costs, making them an eco-friendly choice for your business. With increasing emphasis on sustainable practices, investing in a vertical CNC machining center from SYIL not only benefits your bottom line but also aligns with your commitment to environmental stewardship.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their cost-effective solutions, such as the Flex CNC series, offer competitive pricing while reducing maintenance and operational costs. These machines also incorporate energy-saving features to promote sustainability and environmental responsibility. Choose SYIL as your trusted partner for precision and efficiency in manufacturing.

Excellent Customer Support and Service

At SYIL Machine Tools, we pride ourselves on providing excellent customer support and service to ensure the smooth operation and troubleshooting of our vertical CNC machining centers. Our team of experts is dedicated to assisting you every step of the way, from installation to ongoing maintenance.

Expert Technical Assistance: Ensuring Smooth Operation and Troubleshooting

Our highly skilled technical team is always ready to provide expert assistance, ensuring that your vertical CNC machining center operates seamlessly. Whether you have questions about machine functionality or need help troubleshooting an issue, our technicians are available to offer prompt solutions. With their extensive knowledge and experience, you can rely on us for reliable technical support.

Training and Education: Empowering Operators for Optimal Performance

We understand the importance of empowering operators with the knowledge and skills necessary to maximize the performance of our vertical CNC machining centers. That's why we offer comprehensive training programs tailored to your specific needs. Through hands-on training sessions, operators will learn how to efficiently operate the machine, utilize its advanced features, and troubleshoot common issues. By investing in operator education, we ensure that your team can achieve optimal performance and productivity.

SYIL Machine Tools: A Trusted Partner for Future Business Growth

When you choose SYIL Machine Tools as your partner in precision manufacturing, you gain more than just a supplier – you gain a trusted partner committed to your future business growth. We go above and beyond in providing exceptional customer support and service because we believe in building long-term relationships with our clients. From initial consultation to after-sales support, we are dedicated to meeting your needs and exceeding your expectations.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. As a trusted partner, SYIL offers excellent customer support and service, including expert technical assistance, comprehensive training programs, and a commitment to future business growth. Choose SYIL Machine Tools for precision and efficiency in manufacturing.

Conclusion

Choosing the Right Vertical CNC Machining Center for Your Needs

When it comes to selecting a vertical CNC machining center, it is crucial to consider your specific requirements and production goals. Whether you need high precision and accuracy, versatility and flexibility, reliable performance and durability, or a cost-effective solution, SYIL Machine Tools has got you covered. Their wide range of machines, including the Flex CNC and vertical turning center capability, ensures that there is an option to suit every machining need. By investing in the right vertical CNC machining center, you can take your production capabilities to new heights.

SYIL Machine Tools: The Ultimate Solution for Precision and Efficiency in Manufacturing

SYIL Machine Tools has established itself as a trusted source for precision CNC machines in the industry. With over 12k machines supplied globally, their commitment to quality and sustainability sets them apart from the competition. Their advanced technology and features, such as integrated CAD/CAM software and automatic tool changers, streamline workflow efficiency and increase productivity. Additionally, their Doosan VMC integration ensures proven quality and reliability. When it comes to precision and efficiency in manufacturing, SYIL Machine Tools is the ultimate solution.

Invest in a Vertical CNC Machining Center and Unlock Your Production Potential

Investing in a vertical CNC machining center is a strategic move that can unlock your production potential. The flexibility offered by multi-axis machining allows you to tackle complex workpieces with ease. The adaptable CNC bed caters to various production needs while ensuring consistency and performance through high-quality components. Furthermore, SYIL Machine Tools offers competitive pricing that provides more value for your investment. With reduced maintenance costs and energy-saving features promoting sustainability, investing in a vertical CNC machining center is not only smart but also environmentally responsible.