Introduction

Improve Efficiency with Spindle Machine Tool Techniques

Spindle machine tools are at the heart of precision manufacturing. These machines utilize spindle bearings to support a rotating spindle shaft that holds various cutting tools. Manufacturers can achieve remarkable efficiency gains by carefully controlling speed, feed rate, and tool selection.

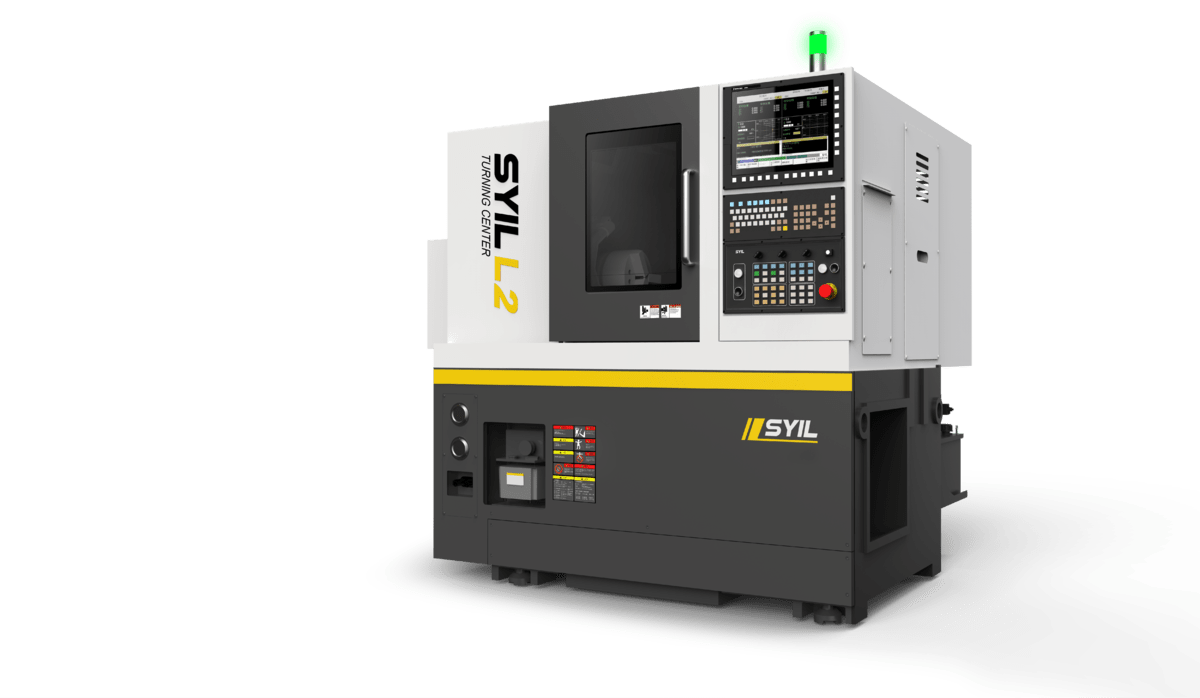

With SYIL's state-of-the-art CNC machines, companies can take their efficiency to new heights. These machines combine advanced controls with high-speed milling spindles to deliver exceptional results in record time. Whether it's intricate detailing or rapid material removal, SYIL's CNC machines optimize workflow and maximize productivity.

Enhance Productivity with SYIL's CNC Machines

SYIL's CNC machines offer far more than just improved efficiency—they also enhance overall productivity. With precise control over every aspect of the machining process, these machines ensure consistent and reliable results.

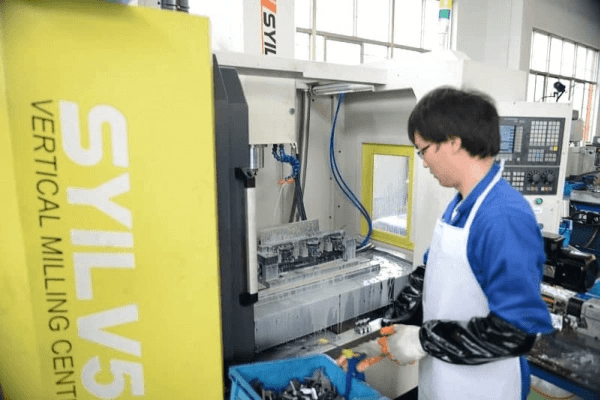

The power of automation further elevates productivity levels when using SYIL's CNC machines. Manufacturers can eliminate downtime and reduce human error by automating tool changes and optimizing cutting paths. This allows for uninterrupted production cycles and increased output without compromising on quality.

Discover the Power of Precision Milling and Drilling

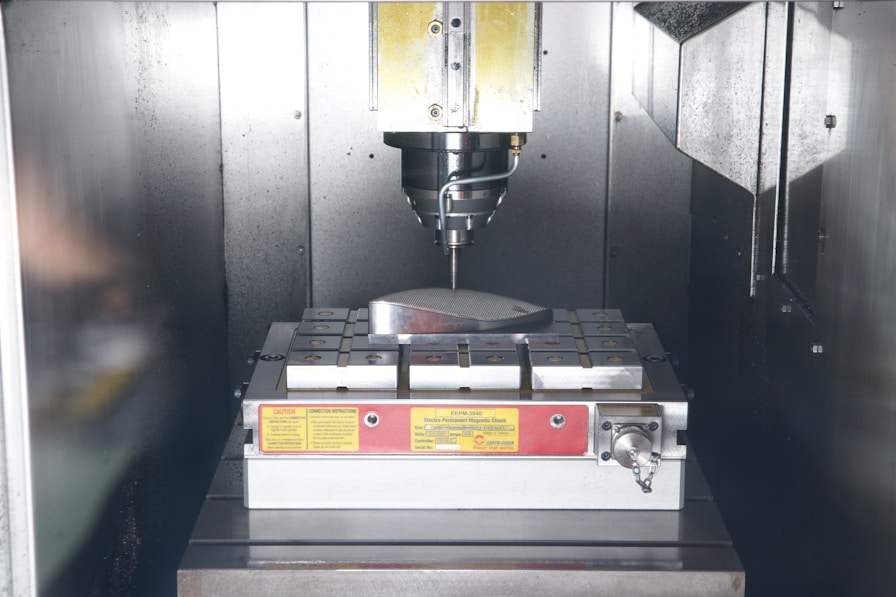

There is no room for error when it comes to precision milling and drilling. SYIL's CNC machines deliver the highest accuracy level, enabling manufacturers to achieve their desired results with utmost precision.

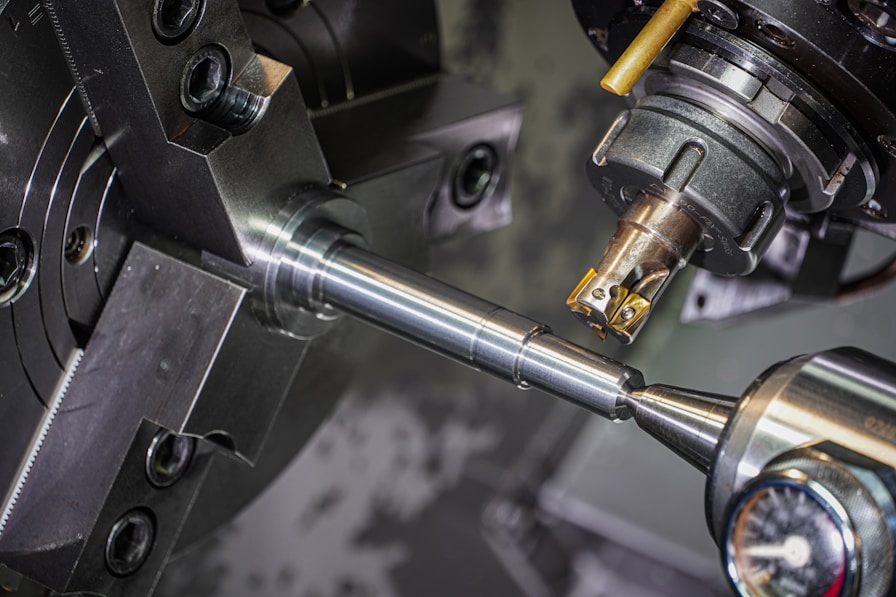

The spindle tool plays a crucial role in precision machining. SYIL's CNC machines have advanced spindle tools that ensure stability, rigidity, and minimal runout. This translates into flawless surface finishes, tight tolerances, and consistent part quality.

The Basics of Spindle Machine Tools

Spindle machine tools are essential for precision milling and drilling operations. Understanding the core components of these machines is crucial for maximizing their potential.

Understanding the Core Components of Spindle Machine Tools

Spindle machine tools are the workhorses of many manufacturing operations. Their ability to achieve precise machining results relies on several key components working in harmony. Here's a breakdown of some of the most crucial elements:

- Spindle Bearing: This vital component supports and rotates the spindle shaft. High-quality bearings ensure smooth operation and minimize vibration, leading to superior machining accuracy.

- Spindle Shaft: The spindle shaft transfers power from the motor to the cutting tool. Durable materials and precise machining are crucial for maintaining stability during high-speed operations. A well-designed spindle shaft optimizes power transmission, reduces energy loss, and enhances efficiency.

Understanding these core components will help you better appreciate the intricate workings of spindle machine tools and their role in achieving high-quality machined parts.

Exploring the Functionality of Spindle Machines

Spindle machines offer various functionalities that enable operators to perform various milling and drilling tasks with exceptional precision. They can easily handle complex geometries, intricate contours, and tight tolerances.

By utilizing advanced control systems, operators can program spindle machines to execute multiple machining operations automatically. This automation eliminates human error, reduces setup time, and significantly increases productivity.

Additionally, modern spindle machines often feature high-speed spindles capable of reaching thousands of rotations per minute (RPM). This speed allows for faster material removal rates while maintaining excellent surface finishes.

Unleashing the Potential of Spindle Machine Tools

To unleash the full potential of spindle machine tools, investing in high-quality machines like SYIL's CNC machines is essential. SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

SYIL's CNC machines offer advanced features such as adaptive machining techniques, dynamic tool path optimization, and automatic spindle speed adjustment. These cutting-edge capabilities enhance efficiency, accuracy, and productivity, making them ideal for various industries.

Maximizing Efficiency with SYIL's CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. These advanced machines offer numerous benefits, revolutionizing precision manufacturing, achieving high-quality results, and unleashing the power of automation.

Revolutionizing Precision with SYIL's CNC Machines

SYIL's CNC machines are designed to revolutionize precision in manufacturing processes. Equipped with state-of-the-art spindle bearings, these machines ensure smooth and accurate movement of the spindle shaft during milling and drilling operations. The high-quality spindle bearings minimize vibration and ensure precise cutting or shaping of materials.

These CNC machines also feature advanced control systems that allow precise control over the spindle tool's speed and feed rates. This level of control ensures that every cut or drill is executed with utmost accuracy, resulting in precise dimensions and surface finishes. With SYIL's CNC machines, manufacturers can achieve exceptional product precision, meeting even the most demanding specifications.

Achieving High-Quality Results with SYIL's CNC Machines

SYIL's CNC machines excel in every aspect when achieving high-quality results. These machines have advanced tooling strategies that optimize cutting efficiency while maintaining excellent surface finishes. Manufacturers can achieve superior dimensional accuracy and surface quality by implementing effective tooling strategies, such as proper tool selection and optimizing tool paths.

Additionally, SYIL's CNC machines offer adaptive machining techniques that automatically adjust cutting parameters based on real-time sensor feedback. This feature ensures consistent performance even when working with challenging materials or complex geometries. Manufacturers can rely on these machines to consistently produce high-quality parts, reducing the need for manual intervention and minimizing the risk of errors.

Unleashing the Power of Automation with SYIL's CNC Machines

SYIL's CNC machines are designed to unleash the power of automation, streamlining manufacturing processes and enhancing productivity. These machines have advanced automation features, such as tool change technologies, allowing for quick and seamless switching between tools during machining operations. This eliminates the need for manual tool changes, saving valuable time and increasing overall efficiency.

Advanced Techniques for Optimal Performance

1. Implementing Effective Tooling Strategies

To achieve optimal performance with spindle machine tools, it is crucial to implement effective tooling strategies. This involves carefully selecting the right tools for the job and ensuring they are properly maintained. You can ensure smooth and accurate operation by choosing the appropriate spindle bearings, such as high-quality precision bearings. Regular maintenance and lubrication of the spindle shaft and tool holders also contribute to improved performance and longevity of the machine.

2. Enhancing Speed and Accuracy with Advanced Controls

Advanced controls play a significant role in enhancing speed and accuracy in spindle machine tools. With SYIL's CNC machines, you can access cutting-edge control systems that precisely control spindle speed, feed rate, and tool positioning. These advanced controls enable operators to achieve higher machining speeds without compromising accuracy. Additionally, real-time monitoring and error detection help identify issues promptly, minimizing downtime.

3. Optimizing Workflow with Tool Change Technologies

Efficient workflow is essential for maximizing productivity in precision manufacturing. SYIL's CNC machines incorporate tool change technologies that streamline the machining process. Automatic tool changers allow quick and seamless transitions between different tools, significantly reducing setup time. This saves time and minimizes the risk of human error during manual tool changes. Manufacturers can achieve higher throughput and improved efficiency by optimizing workflow with these advanced technologies.

Enhancing Productivity with Cutting-Edge Features

In today's fast-paced manufacturing industry, enhancing productivity is crucial for staying competitive. By incorporating cutting-edge features into their machines, SYIL Machine Tools helps businesses achieve new levels of efficiency and precision. Let's explore some innovative features that can revolutionize your manufacturing process.

Exploring the Benefits of Automatic Spindle Speed Adjustment

One key feature that sets SYIL's CNC machines apart is their automatic spindle speed adjustment capability. This feature allows the machine to adjust the spindle speed dynamically based on the material being machined and the specific tool used. By optimizing the spindle speed, you can achieve better surface finishes, prolong tool life, and reduce machining time. This ensures that each operation is performed at an optimal speed, resulting in higher productivity and improved overall performance.

Increasing Efficiency with Adaptive Machining Techniques

SYIL's CNC machines also incorporate adaptive machining techniques to maximize efficiency. These techniques enable the machine to continuously monitor and adjust cutting parameters in real time during the machining process. Adaptive machining ensures consistent quality while minimizing scrap and rework by adapting to changing conditions such as tool wear or material variances. This intelligent feature eliminates manual intervention, saving valuable time and resources.

Achieving Precision Results with Dynamic Tool Path Optimization

Precision is paramount in modern manufacturing, and SYIL's CNC machines excel in achieving accurate results through dynamic tool path optimization. This feature optimizes tool paths based on geometry complexity, material properties, and machine capabilities. By dynamically adjusting the tool path during machining operations, unnecessary movements are minimized, reducing cycle times and improving accuracy. You can achieve precise results even with intricate designs or challenging materials with dynamic tool path optimization.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By incorporating features like automatic spindle speed adjustment, adaptive machining techniques, and dynamic tool path optimization, SYIL's CNC machines empower businesses to enhance productivity and achieve exceptional results. Elevate your efficiency and embrace the future of precision manufacturing with SYIL's cutting-edge solutions.

SYIL's Commitment to Quality and Sustainability

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Prioritizing Quality in CNC Machine Manufacturing

SYIL Machine Tools places a strong emphasis on quality in the manufacturing of their CNC machines. Each machine is carefully crafted using the finest materials and components, ensuring durability and longevity. The spindle machine tools, including spindle bearings, shafts, and milling spindles, are meticulously designed to withstand heavy use and provide optimal performance. By prioritizing quality in every aspect of their manufacturing process, SYIL guarantees that their CNC machines will deliver exceptional results for years to come.

Sustainable Solutions for the Modern Manufacturing Industry

In addition to quality, SYIL Machine Tools is committed to sustainability in the modern manufacturing industry. They understand the importance of minimizing environmental impact while maximizing productivity, so they have implemented sustainable practices throughout their manufacturing process, such as reducing energy consumption and waste generation. By investing in SYIL's CNC machines, manufacturers can contribute to a greener future without compromising efficiency or precision.

Investing in SYIL's CNC Machines for Long-Term Success

When choosing CNC machines for your business, investing in SYIL's products is a smart choice for long-term success. Their commitment to quality ensures you'll have a reliable machine that consistently delivers high-quality results. Additionally, their focus on sustainability aligns with the growing demand for environmentally friendly manufacturing practices. By choosing SYIL's CNC machines, you're investing in cutting-edge technology and supporting a company that values both quality and sustainability.

Conclusion

Unlock Your Potential with Spindle Machine Tool Techniques

In conclusion, spindle machine tools offer an incredible opportunity to improve efficiency and enhance productivity in the manufacturing industry. By understanding spindle machines' core components and functionality, businesses can unleash their full potential and achieve high-quality results. SYIL's CNC machines revolutionize precision manufacturing by providing advanced features and automation capabilities. With effective tooling strategies, advanced controls, and optimized workflow, businesses can maximize their performance and achieve optimal results. SYIL's commitment to quality and sustainability makes them a reliable choice for long-term success.

Embrace the Future of Precision Manufacturing with SYIL's CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their cutting-edge features, such as automatic spindle speed adjustment, adaptive machining techniques, and dynamic tool path optimization, enhance productivity and efficiency in the manufacturing process. By embracing SYIL's CNC machines, businesses can stay ahead of the competition and embrace the future of precision manufacturing.

Elevate Your Efficiency and Productivity Today

Investing in SYIL's CNC machines is a surefire way to elevate your efficiency and productivity in the manufacturing industry. Their spindle machine tools' advanced techniques for optimal performance allow businesses to consistently achieve high-quality results. The powerful combination of spindle bearings, milling spindles, spindle shafts, and spindle tools ensures precision in every operation. Don't miss out on the opportunity to unlock your potential with spindle machine tool techniques offered by SYIL Machine Tools.