Introduction

Cutting aluminum sheets might seem straightforward, but discovering the best way to cut aluminum sheet can make all the difference in your project’s outcome. Whether you're a seasoned fabricator or a DIY enthusiast, understanding how to achieve clean cuts is crucial for both aesthetics and functionality. With a variety of tools and techniques available, knowing what is the best tool to cut aluminum sheets with can save you time, effort, and materials.

Discovering the Best Way to Cut Aluminum Sheet

From hand tools to advanced machinery, exploring options like saws or even CNC machines can lead you toward the optimum method for cutting aluminum sheets effectively. Knowing how do you cleanly cut aluminum sheets will help ensure that you achieve precise edges without unnecessary burrs or damage.

Importance of Accurate Aluminum Cutting Techniques

Accurate cutting techniques are essential not only for achieving a professional finish but also for ensuring safety during the cutting process. When you understand how to cut an aluminium sheet at home or in a workshop setting, you'll reduce waste and enhance efficiency in your projects. Moreover, mastering these techniques will enable you to tackle more complex designs with confidence.

Overview of Tools and Methods Available

There’s an impressive array of tools available for cutting aluminum sheets that cater to different skill levels and project requirements. From circular saws that provide precision cuts to jigsaws that allow for intricate shapes, selecting the right tool is key in achieving your desired results. Additionally, advanced methods like cutting aluminum with a CNC machine offer unparalleled accuracy and repeatability—perfect for professional applications.

Understanding Aluminum Sheet Properties

Characteristics of Aluminum Sheets

Aluminum sheets are known for their corrosion resistance, excellent thermal and electrical conductivity, and malleability. They can be easily formed into different shapes without cracking, which makes them ideal for intricate designs. Additionally, aluminum's lightweight nature means that it can be handled more easily compared to heavier metals—perfect when you're asking yourself what is the best tool to cut aluminum sheets with?

Popular Aluminum Sheet Grades

There are several grades of aluminum sheets available on the market, each with its own unique properties that affect cutting techniques. Common grades include 5052 for marine applications due to its corrosion resistance and 6061 for structural purposes because of its strength and weldability. Knowing which grade you are working with will help you choose the optimum method for cutting aluminum sheets while ensuring a clean finish.

Impact of Thickness on Cutting Techniques

The thickness of an aluminum sheet directly influences your cutting strategy; thicker sheets generally require more powerful tools and specific techniques to achieve clean cuts. For instance, thin sheets may be easily managed with hand tools or jigsaws, while thicker materials often necessitate advanced methods like CNC machining or plasma cutting. Therefore, understanding how thickness impacts your approach is essential—especially when pondering how do you cleanly cut aluminum sheets without damaging them?

Best Tools for Cutting Aluminum Sheets

Exploring Circular Saws for Precision

Circular saws are often hailed as one of the best tools to cut aluminum sheets with precision and ease. Equipped with specialized blades designed for non-ferrous metals, these saws can make quick work of even thicker sheets while ensuring clean cuts without excessive burrs. When using a circular saw, it's essential to maintain a steady hand and use proper clamping techniques to prevent any movement during cutting, which can lead to inaccuracies.

To maximize efficiency, consider using a guide or fence when operating your circular saw; this will help you achieve straight cuts consistently. Additionally, pre-marking your cutting lines can serve as a visual aid and help ensure that you don’t stray off course while executing those clean cuts. Ultimately, mastering the use of circular saws can significantly elevate your ability to cut aluminum sheets accurately.

The Role of Jigsaws in Sheet Cutting

Jigsaws might not be the first tool that comes to mind when considering how do you cleanly cut aluminum sheets, but they have their merits too! These versatile tools excel at making intricate cuts and curves in aluminum sheets that larger saws might struggle with. With the right blade—specifically designed for metal—you’ll find that jigsaws can handle thinner gauges quite well.

One benefit of using a jigsaw is its portability; it’s easy to maneuver in tight spaces where larger equipment may not fit comfortably. However, keep in mind that while jigsaws are great for detailed work, they may not provide the same level of speed or efficiency as other cutting methods when tackling larger pieces of aluminum sheet stock. So if you're wondering about how to cut an aluminium sheet at home with finesse and creativity, don't overlook this handy tool!

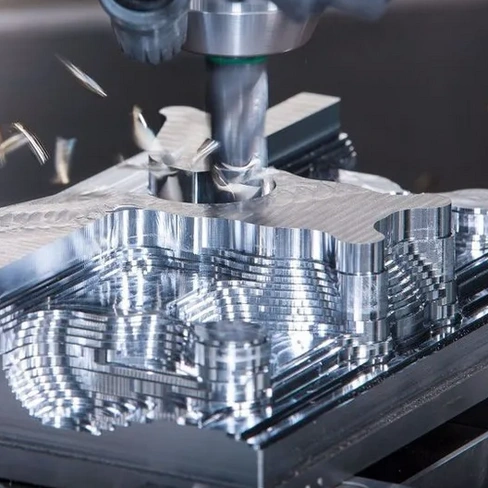

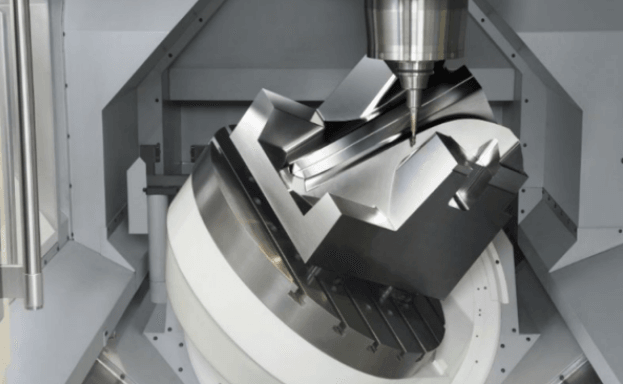

Benefits of Using a SYIL CNC Machine

For those seeking what is the optimum method for cutting aluminum sheets, investing in a SYIL CNC machine could be your golden ticket! These advanced machines offer unparalleled precision and repeatability when it comes to processing aluminum materials—making them ideal for both small-scale projects and large manufacturing runs alike. With computer-controlled operations, CNC machines eliminate human error and allow complex designs that would be nearly impossible with manual tools.

Cutting Aluminum with a CNC Machine also means less physical strain on the operator since much of the heavy lifting is done by the machine itself—allowing craftsmen more time to focus on design rather than labor-intensive tasks. Moreover, many CNC machines come equipped with cooling systems that help reduce heat buildup during cutting processes; this ensures cleaner edges and prolongs tool life significantly compared to traditional methods. If you're serious about achieving high-quality results efficiently every time you cut aluminum sheets, then embracing technology like SYIL CNC machines is definitely worth considering.

Techniques for Clean Cuts

How to Cleanly Cut Aluminum Sheets

To cleanly cut aluminum sheets, start by securing them firmly on a stable surface to prevent any movement during cutting. The choice of tool is crucial; using a blade designed specifically for metal can make all the difference. For those wondering what is the best tool to cut aluminum sheets with, consider options like circular saws or jigsaws equipped with fine-toothed blades for smooth cuts.

It's also important to adjust your cutting speed based on the thickness of the aluminum sheet; slower speeds typically yield cleaner edges. Additionally, lubricating the cutting area can help minimize friction and reduce burr formation, ensuring that you achieve optimal results every time you cut an aluminium sheet at home.

Tips for Using a Bandsaw Efficiently

Using a bandsaw is one of the most effective methods when considering how do you cleanly cut aluminum sheets. To maximize efficiency, ensure that your bandsaw blade is sharp and suitable for metalwork; dull blades can lead to jagged edges and increased heat generation. Positioning your material correctly and making gradual cuts will not only enhance precision but also extend the life of your bandsaw blade.

Another tip when using a bandsaw is to maintain consistent pressure while guiding the material through the blade—this helps in achieving uniformity across all cuts. By practicing these techniques, you'll discover what is the optimum method for cutting aluminum sheets with this versatile tool.

Avoiding Common Cutting Mistakes

Even seasoned DIYers can make mistakes when it comes to cutting aluminum sheets, so being aware of common pitfalls can save time and materials. One major mistake is rushing through cuts; taking your time ensures accuracy and reduces waste from miscuts or damaged materials. Also, neglecting proper safety gear—such as gloves and goggles—can lead to accidents that could easily be avoided with just a bit of forethought.

Another common error involves failing to measure twice before cutting; this age-old adage holds true in metalworking as well! Lastly, if you're considering cutting Aluminum with a CNC machine, ensure you've calibrated it correctly before starting any project—this will help avoid costly errors down the line.

DIY Methods for Home Cutting

Cutting aluminum sheets at home can be a rewarding project that allows you to create custom pieces for various applications. Whether you're working on a DIY project or just need to trim some metal, knowing the best way to cut aluminum sheet is essential. In this section, we'll explore how to cut an aluminum sheet at home, the tools you'll need, and crucial safety tips.

How to Cut an Aluminum Sheet at Home

When it comes to cutting aluminum sheets at home, there are several effective methods you can employ depending on your available tools and the thickness of the sheet. For thinner sheets (up to 1/8 inch), using hand tools like a hacksaw or tin snips can yield clean cuts without much hassle. However, if you're dealing with thicker materials, consider using a circular saw equipped with a fine-toothed blade specifically designed for cutting metals—this is often regarded as one of the best ways to cut aluminum sheet efficiently.

If precision is key for your project, you might want to invest in a jigsaw or bandsaw fitted with a metal-cutting blade. These tools allow for intricate cuts and curves that hand tools can't achieve easily. Remember that regardless of the tool you choose, securing your aluminum sheet properly before cutting will help prevent any unwanted movement and ensure cleaner results.

Utilizing Hand Tools for DIY Projects

For smaller projects or detailed work, tin snips can also come in handy as they allow you greater control over intricate shapes or curves—just remember that they work best on thinner sheets! If you're looking for an affordable option without compromising quality, investing in good-quality hand tools will serve you well in your DIY endeavors.

Safety Tips for Home Projects

Safety should always be your top priority when working with any cutting methods at home—especially when handling metal materials like aluminum sheets! Always wear appropriate protective gear such as safety glasses and gloves; this will protect your eyes from flying debris and your hands from sharp edges after making cuts. Additionally, ensure that your workspace is well-ventilated if you're using power tools.

Before starting any cutting process, double-check all measurements and markings on your aluminum sheet; it’s better to measure twice than regret once! Lastly, keep all bystanders away from your work area while operating machinery or power tools—it's not just about protecting yourself but ensuring everyone's safety around you too!

Advanced Cutting Techniques

What is the Optimum Method for Cutting Aluminum Sheets?

The optimum method for cutting aluminum sheets often depends on your specific project requirements and available tools. For general purposes, using a circular saw with a fine-tooth blade is frequently considered one of the best tools to cut aluminum sheets with precision. If you’re looking for intricate designs or detailed work, CNC machining might just be your best bet; it allows for complex cuts while maintaining accuracy and speed.

Understanding how to cleanly cut aluminum sheets involves choosing the right blade and ensuring that your equipment is set up correctly. A sharp blade designed specifically for metal will help reduce burrs and ensure a smooth finish. Ultimately, evaluating your needs will guide you in selecting the best methods tailored to your project.

Cutting Aluminum with a CNC Machine

Cutting aluminum with a CNC machine offers unparalleled precision and repeatability, making it an ideal choice for both small-scale projects and large production runs. The computer-controlled nature of CNC machines allows you to execute complex designs that would be challenging or impossible with manual tools. This method not only improves efficiency but also reduces waste by maximizing material usage.

Moreover, CNC machines can handle various thicknesses of aluminum sheet—making them versatile across different applications—from automotive parts to intricate decorative elements. If you’re serious about achieving high-quality cuts consistently, investing in CNC technology might be worth considering as part of your toolkit for cutting aluminum sheets effectively.

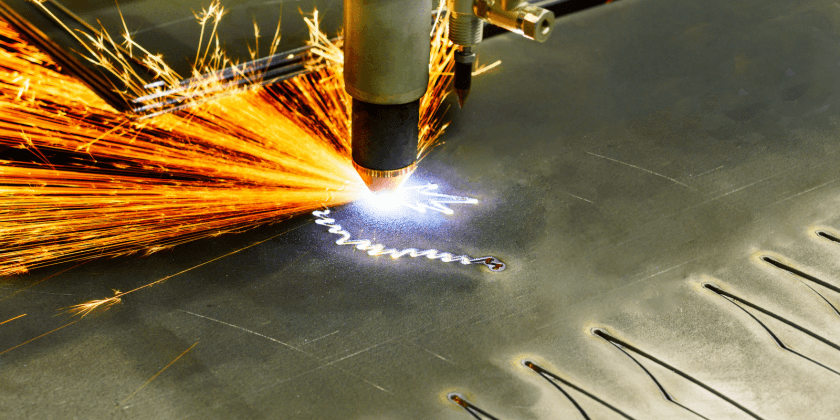

Advantages of Laser Cutting and Waterjet Technology

When exploring advanced techniques in cutting aluminum sheets, laser cutting and waterjet technology stand out due to their remarkable capabilities. Laser cutting provides incredibly precise cuts without contact with the material, minimizing distortion while producing smooth edges—truly an optimal method when dealing with delicate designs or thin materials.

On the other hand, waterjet technology excels at handling thicker materials without generating heat-affected zones that could compromise structural integrity. This makes it an excellent option if you're working with heavy-duty applications where precision is still paramount but thickness poses challenges.

Both methods offer unique advantages depending on your project's needs—whether it's speed, accuracy, or material type—making them worthy contenders when considering how to cut an aluminium sheet at home or in a professional setting.

Conclusion

In summary, mastering the best way to cut aluminum sheet involves understanding the tools and techniques that suit your project needs. From circular saws to CNC machines, each method offers unique advantages for achieving clean, precise cuts. By selecting the right tool and approach, you can ensure a successful outcome for your aluminum cutting endeavors.

Recap of Effective Aluminum Cutting Tools

When considering what is the best tool to cut aluminum sheets with, it's essential to weigh your options carefully. Circular saws provide speed and precision for larger sheets, while jigsaws are perfect for intricate cuts. For those seeking advanced solutions, cutting aluminum with a CNC machine or utilizing laser cutting technology can yield exceptional results with minimal effort.

Choosing the Right Method for Your Needs

Selecting the optimum method for cutting aluminum sheets largely depends on your specific project requirements and available resources. If you're working on a DIY project at home, knowing how to cut an aluminium sheet at home using hand tools can be invaluable. However, if precision is crucial or if you're handling thicker materials, investing in advanced tools like a CNC machine may be worth considering.

Final Thoughts on Cutting Aluminum Sheets Efficiently

Ultimately, learning how do you cleanly cut aluminum sheets will save you time and frustration in the long run. Whether you're using basic hand tools or high-tech machinery, understanding each method's strengths will help you achieve better results consistently. So gear up with the right tools and techniques—your next aluminum cutting project is bound to be a success!