Introduction

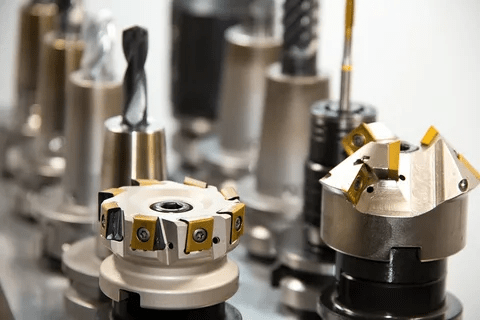

Discover the Power of Multi-Tool CNC Machines, as SYIL CNC Machines Revolutionize Precision Engineering, allowing you to Unleash Efficiency with the Ultimate CNC Tools.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. These multi-tool CNC machines are designed to maximize productivity by combining multiple tools into one, streamlining workflows with automated tool changes, and enabling precision engineering for complex projects.

Discover the Power of Multi-Tool CNC Machines

Multi-tool CNC machines offer a game-changing solution for precision engineering. By integrating multiple tools into a single machine, these advanced systems eliminate the need for manual tool changes and significantly reduce downtime. With SYIL's multi-tool CNC machines, you can achieve higher productivity and efficiency in your machining processes.

How SYIL CNC Machines Revolutionize Precision Engineering

SYIL's CNC machines revolutionize precision engineering by offering unparalleled versatility. With their multi-tool capabilities, these machines allow you to perform various machining operations without needing separate equipment or setups. This saves time and ensures consistent accuracy throughout your manufacturing process.

Unleash Efficiency with the Ultimate CNC Tools

SYIL's multi-tool CNC machines provide the ultimate solution for efficiency in precision engineering. Combining different tools into one machine can streamline your workflow and optimize production processes. Whether milling, drilling, or any other machining operation, these versatile machines deliver exceptional results while reducing costs and increasing overall efficiency.

The Versatility of Multi-Tool CNC Machines

Multi-tool CNC machines offer a range of benefits that can greatly enhance productivity and efficiency in precision engineering projects. Because they can accommodate multiple tools in one machine, these versatile devices are revolutionizing the industry.

Maximizing Productivity with Multiple Tools in One

By incorporating multiple tools into a single CNC machine, manufacturers can maximize productivity and reduce downtime. With different tools readily available, operators can seamlessly switch between tasks without manual tool changes or interruptions.

SYIL Machine Tools understands the importance of efficiency in today's fast-paced manufacturing environment. Their multi-tool CNC machines allow users to easily perform various operations such as milling, drilling, and cutting. This versatility translates into significant time savings and increased output.

Streamlining Workflow with Automated Tool Changes

One key advantage of multi-tool CNC machines is their ability to automate tool changes. Instead of manually swapping out tools for different tasks, these machines can automatically switch between tools based on pre-programmed instructions.

SYIL's CNC machines have advanced tool change systems that ensure seamless transitions between operations. This automation eliminates the need for human intervention and reduces the risk of errors or delays during tool changes.

Precision Engineering for Complex Projects

Multi-tool CNC machines excel at handling complex projects that require precise engineering solutions. With a variety of tools, manufacturers can tackle intricate designs and achieve unparalleled accuracy.

SYIL Machine Tools understands the demands of precision engineering and has developed its multi-tool CNC machines to meet these challenges head-on. Whether creating intricate patterns or drilling precise holes, SYIL's machines always deliver exceptional results.

SYIL CNC Machines: Setting the Standard

SYIL Machine Tools: A Leading Name in Precision CNC Technology

SYIL Machine Tools is a renowned manufacturer and developer of precision CNC machines for milling and drilling. With a global reach and over 12,000 machines supplied worldwide, SYIL has established itself as a leading name in the industry. Their commitment to innovation and quality has earned them the trust of countless professionals in various fields.

Quality Engineering for Unparalleled Performance

At SYIL, quality engineering is at the heart of everything they do. Each CNC machine tool is meticulously designed and crafted to deliver unparalleled performance. From selecting high-grade materials to rigorous testing procedures, every step is taken to ensure that their machines meet the highest standards of excellence.

Sustainability at the Core of SYIL's Manufacturing Process

SYIL recognizes the importance of sustainability in today's world. They are dedicated to minimizing their environmental impact by implementing eco-friendly practices throughout their manufacturing process. From energy-efficient operations to responsible waste management, SYIL strives to be a leader in sustainable manufacturing.

With its commitment to quality, sustainability, and innovative technology, SYIL Machine Tools has become a trusted partner for precision engineering needs. Whether you're working on intricate projects or large-scale productions, its multi-tool CNC machines provide unmatched efficiency and accuracy.

Unleashing Efficiency with CNC Tool Holders

CNC tool holders are crucial in enhancing precision and stability in machining operations. With SYIL CNC machines, you can expect reliable holders that ensure optimal performance and accuracy.

Enhancing Precision and Stability with Reliable Holders

SYIL Machine Tools understands the importance of precision in machining processes. That's why its CNC tool holders are designed to provide exceptional stability, minimize vibrations, and ensure precise cuts and drilling.

Using high-quality materials and advanced manufacturing techniques, SYIL creates tool holders that can withstand the demands of heavy-duty machining. This means you can rely on their holders to maintain accuracy even during prolonged use.

Boosting Productivity with Quick and Easy Tool Changes

Efficiency is key in any machining operation, and SYIL CNC tool holders also excel in this aspect. You can minimize downtime and maximize productivity with quick and easy tool changes.

SYIL's tool holders are engineered for seamless integration with their multi-tool CNC machines. The user-friendly design allows for swift tool swaps, reducing setup time and enabling uninterrupted workflow.

SYIL CNC Tool Holders: The Perfect Fit for Every Job

No matter the project, SYIL has many CNC tool holders to meet your needs. From end mill holders to collet chucks, they offer a comprehensive selection of holders that ensure compatibility with various cutting tools.

With SYIL's commitment to precision engineering, you can trust that its toolholders will provide a perfect fit for every job. Whether you're working on milling or drilling applications, their versatile range of holders will help you achieve optimal results.

The Advantages of CNC Tool Changers

CNC tool changers offer several advantages that enhance efficiency and productivity in precision engineering. Workers can seamlessly transition between different tools without wasting valuable time by reducing downtime with rapid tool swapping. This allows for uninterrupted workflow and maximizes output. Additionally, customizing workflows for maximum efficiency ensures that each task is completed in the most optimized manner possible. SYIL's tool changer for CNC routers takes these advantages to the next level, particularly in woodworking applications.

Rapid tool swapping is a game-changer that reduces downtime in CNC machining. With traditional manual tool changes, operators must stop the machine, manually remove the current tool, and install the new one. This process consumes time and increases the risk of human error. However, this process is automated with CNC tool changers and can be completed within seconds. This means less idle time and more production time, ultimately leading to higher overall efficiency.

Customizing workflows is crucial in achieving maximum efficiency in precision engineering projects. Each project may require a unique combination of tools to achieve the desired outcome. With CNC tool changers, operators can easily program the machine to follow specific tool change sequences based on the project requirements. This eliminates manual intervention and ensures that each task is completed with minimal effort and optimal results.

SYIL's tool changer for CNC routers brings these advantages specifically to woodworking applications. Woodworking projects often involve multiple tools, such as drills, saws, and routers, that must be swapped frequently depending on the desired design or cut. SYIL's tool changer simplifies this process by automatically swapping out tools based on pre-programmed instructions or commands from the operator. This not only saves time but also reduces errors during manual changes.

SYIL Machine Tools understands the importance of efficiency and precision in modern manufacturing. Their CNC machines, equipped with advanced tool changers, empower engineers and craftsmen to achieve unparalleled productivity. By investing in SYIL's CNC machines, businesses can unlock the full potential of their manufacturing processes and stay ahead of the competition.

In conclusion, CNC tool changers provide significant advantages in reducing downtime and customizing workflows for maximum efficiency. SYIL's tool changer for CNC routers specifically revolutionizes woodworking applications by automating the tool swapping. With SYIL Machine Tools as your partner in precision engineering, you can embrace the future of manufacturing and unleash efficiency like never before.

Precision Engineering with SYIL CNC Tools

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Achieving Unmatched Accuracy in Milling and Drilling

SYIL CNC tools are designed to deliver unmatched accuracy in milling and drilling operations. The advanced technology and precise engineering ensure that every cut and hole is made with utmost precision. Whether you're working on small, intricate parts or large-scale projects, SYIL CNC tools guarantee the highest level of accuracy, resulting in flawless finished products.

Unleashing Creativity with Customizable Tool Paths

One of the key advantages of SYIL CNC tools is the ability to unleash creativity through customizable tool paths. With the flexibility to program tool movements, users can easily create intricate designs and complex shapes. From curves to angles, SYIL CNC tools allow for endless possibilities, enabling users to bring their creative visions to life.

SYIL's Tool Setter CNC: Ensuring Precise Tool Calibration

Precise tool calibration is essential to achieving optimal performance and accuracy. That's where SYIL's Tool Setter CNC comes into play. This innovative tool ensures that each cutting or drilling tool is calibrated accurately, eliminating potential errors or discrepancies. With the Tool Setter CNC, you can trust that your tools are perfectly calibrated for consistent results every time.

Remember, regarding precision engineering in milling and drilling operations, SYIL Machine Tools has covered you. Their advanced CNC tools offer unmatched accuracy, customizable tool paths for creative freedom, and precise tool calibration for consistent performance.

Conclusion

Unleash Efficiency and Precision with SYIL CNC Machines

SYIL Machine Tools has revolutionized precision engineering with its multi-tool CNC machines. These machines offer the power and versatility to maximize productivity, streamline workflows, and achieve unmatched accuracy in milling and drilling. With SYIL's commitment to quality engineering and sustainability, they have become a leading name in the industry.

SYIL Machine Tools: Your Partner in Precision Engineering

When it comes to precision engineering, SYIL Machine Tools is the partner you can trust. With over 12k machines supplied globally, they have established themselves as a reliable manufacturer of CNC machines for milling and drilling. Their focus on quality ensures unparalleled performance, while their commitment to sustainability sets them apart from the competition.

Embrace the Future of Manufacturing with Multi-Tool CNC Technology

The future of manufacturing lies in multi-tool CNC technology, and SYIL Machine Tools is at the forefront of this innovation. Their CNC tool holders provide enhanced precision and stability, while their tool changers reduce downtime with rapid tool swapping. Whether you're in woodworking or any other industry that requires precision engineering, SYIL's CNC machines are the perfect fit for every job.

In conclusion, if you want to unleash efficiency and precision in your manufacturing processes, look no further than SYIL Machine Tools. Their CNC machines offer unmatched productivity, accuracy, and versatility. With their reliable tool holders and innovative tool changers, you can customize your workflows for maximum efficiency. Embrace the future of manufacturing with SYIL's multi-tool CNC technology today!