Introduction

In CNC machining, the choice of CNC rotary table manufacturers can make all the difference in the efficiency and precision of your operations. When selecting a rotary table manufacturer, it's crucial to consider factors such as reputation, experience, and the level of customization offered. Investing in a quality CNC rotary table can enhance accuracy, productivity, and overall performance for your machining needs.

The Importance of Choosing the Right CNC Rotary Table Manufacturers

Choosing the proper CNC rotary table manufacturer is vital for ensuring seamless integration with your machine and optimizing its capabilities. With an array of manufacturers in the market, it's essential to carefully evaluate their expertise and track record to make an informed decision that aligns with your machining requirements.

Key Factors to Consider When Selecting a Rotary Table Manufacturer

When selecting a rotary table manufacturer, it's essential to consider factors such as precision, durability, customization options, and technological advancements. These key factors significantly determine the overall quality and functionality of the rotary table within your CNC machine setup.

Benefits of Investing in a Quality CNC Rotary Table

CNC machining efficiency gets a boost with a high-quality rotary table. Here's why:

- Precise Positioning and Rotation: The rotary table allows for accurate and smooth movement of your workpiece, minimizing setup time and ensuring consistent results.

- Faster Machining Operations: Machining processes become quicker and more efficient with precise positioning, leading to increased output.

- Reduced Production Costs: By saving time on setup and execution, a rotary table can significantly reduce overall production costs.

- Improved Overall Performance: By incorporating a rotary table, you unlock the full potential of your CNC machine, maximizing its efficiency and overall performance.

Investing in a quality rotary table is a strategic decision that optimizes your machining processes, saves time and money, and ultimately enhances the performance of your CNC machine setup.

Reputation and Experience

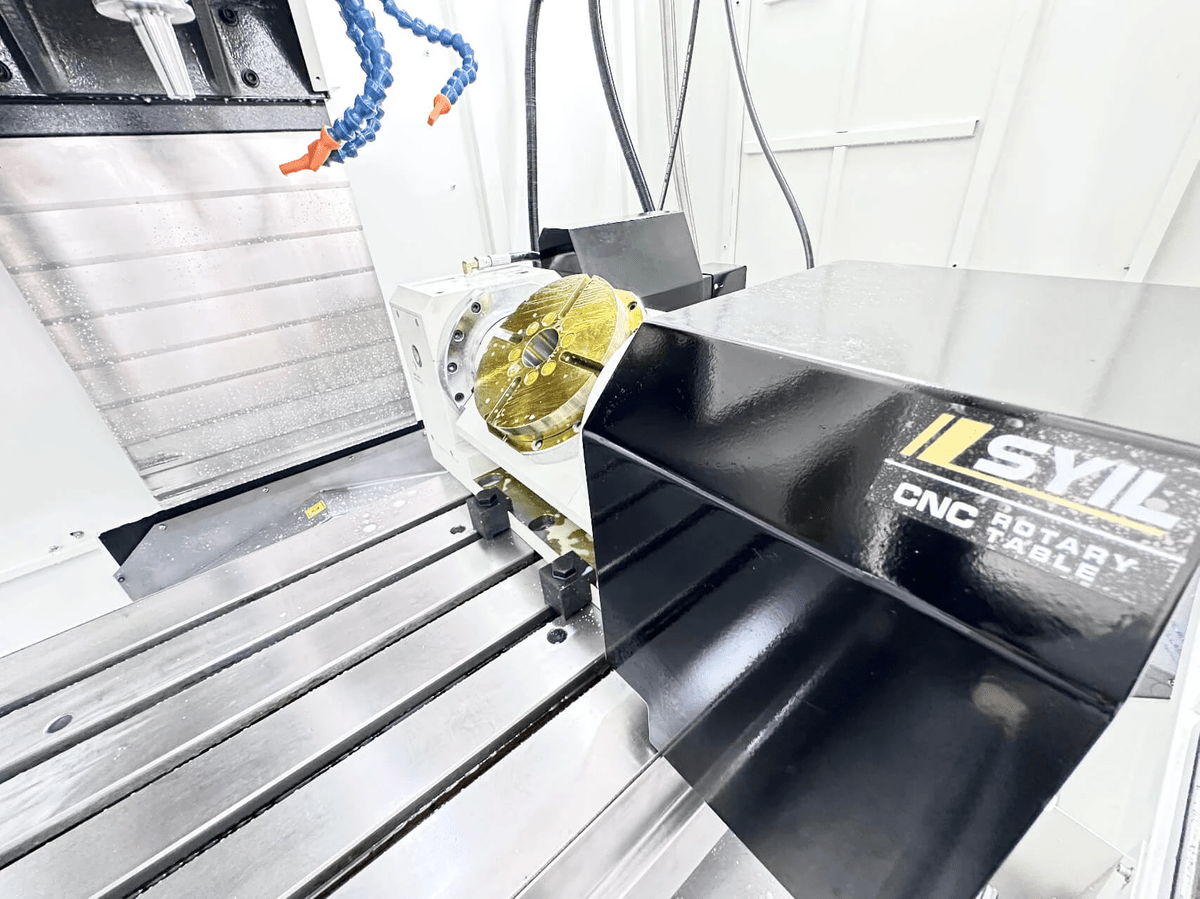

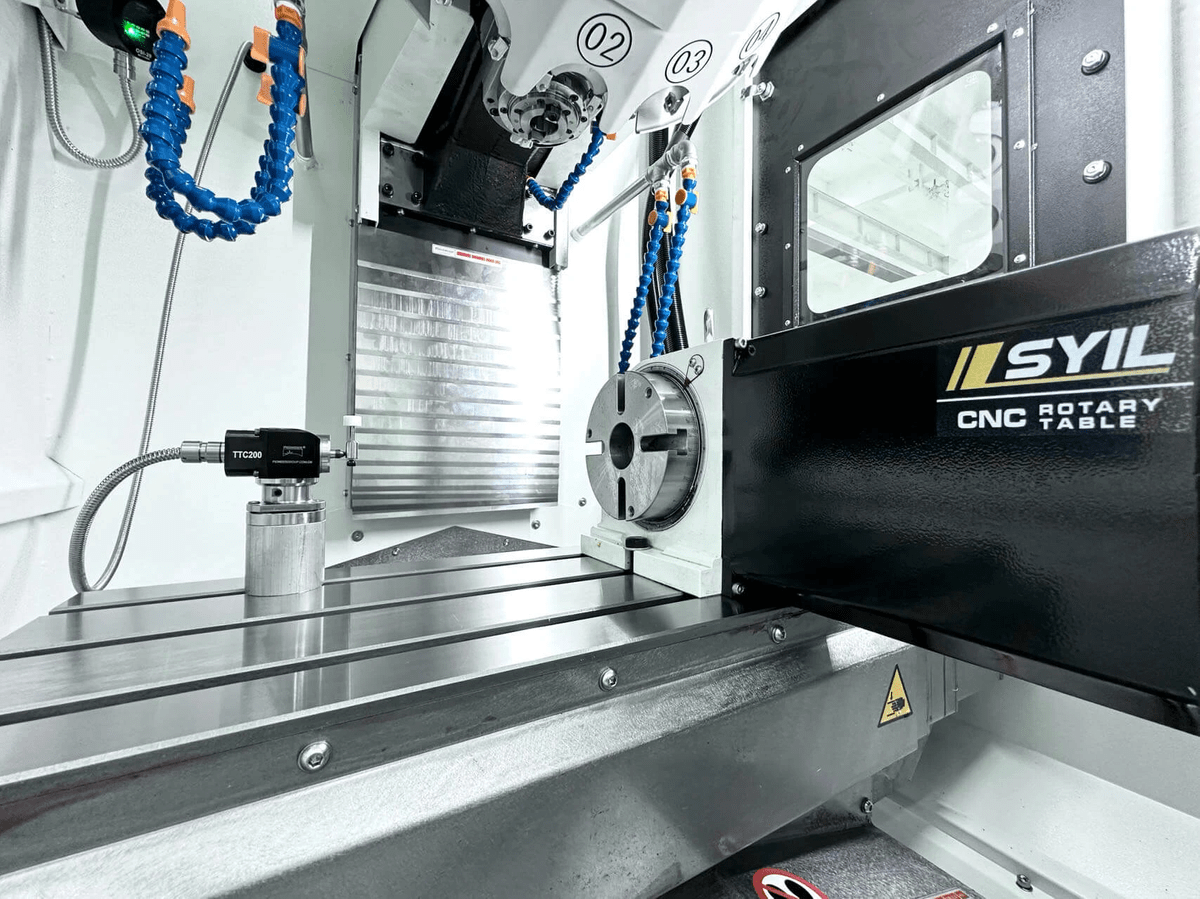

SYIL CNC Machine: A Leading Name in CNC Machine Manufacturing

Regarding CNC machine manufacturing, SYIL has established itself as a leading name in the industry. With a strong focus on quality and innovation, SYIL has consistently delivered top-notch products, including their range of CNC rotary tables.

The Significance of Long-standing Experience in the CNC Machining Industry

SYIL has established itself as a trusted name in CNC machining through its extensive experience. Here's what sets them apart:

- Years of Expertise: With a long-standing presence in the industry, SYIL has honed its skills and knowledge to deliver exceptional results.

- Perfected Processes: Through years of experience, they have refined their manufacturing processes to ensure consistent production of high-quality rotary tables.

- Proven Reputation: Their commitment to quality and customer satisfaction has earned them a strong reputation as a reliable manufacturer.

By choosing SYIL, you're selecting a partner with the experience and expertise to deliver superior rotary tables for your CNC machining needs. Their dedication to quality ensures you receive reliable and long-lasting equipment.

How Reputation Reflects the Quality of CNC Rotary Tables

SYIL's reputation speaks volumes about the quality of its CNC rotary tables. Their commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry, making them a trusted choice for businesses looking for reliable and durable rotary machining solutions. Furthermore, SYIL's dedication to innovation and continuous improvement ensures that its CNC rotary tables are always at the forefront of technological advancements, providing customers with cutting-edge solutions for their machining needs. In addition, the positive reviews and testimonials from satisfied customers further solidify SYIL's reputation as a leading provider of high-quality CNC rotary tables.

By choosing SYIL as your partner in CNC machining, you can rest assured that you are investing in top-of-the-line products backed by years of experience and a solid reputation.

Precision and Durability

The Role of Precision in CNC Machining

Precision is crucial in CNC machining, as it directly impacts the accuracy and quality of the finished product. Without precise movements and measurements, the entire manufacturing process can be compromised, leading to costly errors and rework.

SYIL CNC Rotary Tables: Exemplary Precision and Longevity

SYIL CNC Machine is known for producing rotary tables with exemplary precision and longevity. Their advanced technology and meticulous engineering ensure that their rotary tables deliver consistent accuracy and reliability, meeting the high demands of modern machining operations. In addition, SYIL CNC Rotary Tables are designed to withstand heavy-duty usage, making them an ideal choice for industrial applications where durability is essential. This means that operators can rely on SYIL CNC Rotary Tables to perform consistently over time, reducing the need for frequent maintenance or replacement.

Ensuring Durability in CNC Rotary Table Selection

Durability is a key consideration when selecting a CNC rotary table to ensure long-term performance and minimal maintenance requirements. SYIL's commitment to using high-quality materials and rigorous testing processes guarantees that its rotary tables are built to withstand the rigors of heavy-duty machining operations.

SYIL's dedication to durability is evident in its use of high-quality materials, such as hardened steel and precision bearings, which are essential for withstanding the demanding conditions of CNC machining. Additionally, their rotary tables undergo rigorous testing to ensure they meet the highest standards for durability and performance. This commitment to quality and reliability translates to minimal maintenance requirements and long-term cost savings for businesses utilizing SYIL's rotary table solutions.

Partnering with SYIL CNC Machine for unparalleled precision and durability in rotary table solutions ensures that your machining processes consistently produce high-quality results without compromising longevity or performance.

Customization and Flexibility

Tailored Solutions Offered by Top CNC Rotary Table Manufacturers

When it comes to CNC machining, having a tailored solution can make all the difference in achieving optimal results. Top CNC rotary table manufacturers understand the importance of customization and offer various options to suit specific machining needs. With a focus on precision and flexibility, these manufacturers ensure that their rotary tables can be tailored to meet the unique requirements of different applications.

The Importance of Flexibility in CNC Machine Operations

In CNC machining, maximizing flexibility is crucial for handling diverse production demands. A rotary table is a critical component that unlocks this potential:

- Multi-Axis Machining: Rotary tables enable machining on multiple axes simultaneously, allowing for complex parts and intricate features to be completed in a single setup.

- Expanded Operations: Beyond milling, rotary tables facilitate drilling and grinding at various angles, streamlining workflows.

- Enhanced Productivity: Reduced setup times and the ability to perform multi-axis machining translate to increased output and efficiency.

- Innovation Opportunities: The ability to manipulate parts on multiple axes opens doors for innovative design and manufacturing techniques.

- Customizable Solutions: SYIL CNC Machine offers customizable rotary tables, allowing manufacturers to tailor the equipment to their specific needs and optimize their unique production processes.

Manufacturers gain a powerful tool for increased flexibility, productivity, and innovative exploration by incorporating a rotary table into their CNC machining setup.

SYIL CNC Machine: Offering Customizable Rotary Table Solutions

SYIL CNC Machine is a leading provider of customizable rotary table solutions for diverse machining needs. Committed to precision engineering and advanced technology, SYIL offers a range of indexing tables that can be customized to fit specific machine configurations and production requirements. This flexibility ensures seamless integration with existing systems while enhancing overall performance and efficiency.

Manufacturers can optimize their CNC machining operations by choosing SYIL's customizable rotary table solutions, which offer tailored precision and unparalleled flexibility.

Advanced Technology and Innovation

In today's competitive CNC machining industry, embracing technological innovation is crucial for staying ahead of the curve. With the rapid advancements in CNC technology, partnering with a manufacturer at the forefront of innovation is essential.

Embracing Innovation in CNC Machining Technology

As CNC machining continues to evolve, the demand for more advanced and efficient solutions grows. Manufacturers constantly innovate to meet these demands, developing new technologies that enhance precision, speed, and versatility in machining operations.

SYIL CNC Machine: Pioneering Advanced Technology in Rotary Table Manufacturing

SYIL CNC Machine stands out as a leader in pioneering advanced technology in rotary table manufacturing. Committed to continuous improvement, SYIL integrates cutting-edge innovations into its rotary tables, ensuring top-notch performance and reliability.

The Impact of Cutting-edge Technology on CNC Machine Performance

Cutting-edge technology is revolutionizing CNC machining, significantly improving various aspects. Here's how:

- Enhanced Accuracy and Repeatability: Advanced components and control systems minimize errors and ensure consistent results, crucial for high-precision manufacturing.

- Boosted Automation and Integration: Modern CNC machines can integrate with robots and automated systems, streamlining workflows and minimizing human intervention.

- Real-Time Monitoring and Adjustments: Sophisticated software allows for continuous machining process monitoring, enabling operators to identify and address issues promptly.

- Improved Quality Control and Reduced Waste: Real-time adjustments and data analysis minimize errors and material waste, leading to higher-quality products.

- Predictive Maintenance and Optimized Scheduling: Advanced sensors and data analytics predict potential maintenance needs and optimize production schedules for maximum efficiency.

By embracing cutting-edge technology, CNC machining operations benefit from improved accuracy, automation, and real-time process control, ultimately leading to higher quality, efficiency, and productivity.

Customer Support and Service

Customer service plays a crucial role in selecting CNC rotary table manufacturers. When investing in a precision instrument like a rotary table, reliable support throughout the process is essential. SYIL CNC Machine understands this need and goes above and beyond to provide exceptional customer service, ensuring clients have all the required information and assistance.

The Role of Customer Service in CNC Rotary Table Selection

Choosing the proper CNC rotary table manufacturer involves more than just the product itself; it's about the overall experience. From initial inquiries to post-purchase support, top-notch customer service can make all the difference. At SYIL CNC Machine, we prioritize customer satisfaction by offering personalized guidance and expert advice to help clients make informed decisions when selecting a rotary table that perfectly suits their needs.

SYIL CNC Machine: Providing Exceptional Customer Support

SYIL CNC Machine takes pride in offering unparalleled customer support at every stage of the purchasing process. Our team of knowledgeable professionals is dedicated to addressing any queries or concerns promptly, ensuring that clients feel confident and supported from start to finish. With our commitment to excellence, we strive to exceed expectations and build lasting relationships with our valued customers.

Ensuring a Seamless Experience with After-sales Service

Furthermore, our after-sales service extends beyond just technical support. We also offer regular maintenance and training programs to ensure our clients get the most out of their investment. Our team is dedicated to providing ongoing education and support to help users optimize their rotary table's performance and efficiency. With SYIL, customers can rest assured that they have a partner in their success, not just a product supplier.

The Future of CNC Machining with SYIL CNC Rotary Tables

When choosing the right CNC rotary table manufacturers, it's crucial to consider factors such as reputation, precision, customization, and customer support. With SYIL CNC Machine, you can rest assured that you're partnering with a company that excels in all these areas. Their commitment to advanced technology and innovation ensures that the future of CNC machining is in good hands.

Making the Right Choice in CNC Rotary Table Manufacturers

Selecting the proper CNC rotary table manufacturer is a decision that shouldn't be taken lightly. It's essential to thoroughly research and consider factors such as reputation, experience, precision, and customer support. SYIL CNC Machine stands out as a top choice, offering unparalleled quality and service that sets them apart from other manufacturers.

Partnering with SYIL CNC Machine for Unparalleled Quality and Service

When investing in CNC rotary tables, partnering with SYIL CNC Machine is a no-brainer. Their dedication to precision, durability, customization, and customer support ensures you'll receive top-notch products and services every step. With their expertise and cutting-edge technology, you can trust that your machining needs are in good hands.

As technology continues to advance rapidly, the future of CNC machining looks bright, with SYIL's innovative rotary tables leading the way. Their commitment to embracing advanced technology and providing tailored solutions positions them as industry leaders in rotary table manufacturing. By choosing SYIL for your machining needs, you're investing in the future of precision engineering.